Based on the principle of "quality-oriented, customer-driven, honesty essential", as well as the business philosophy of "leading in science and technology, pioneering and innovative, win-win cooperation", we continuously strengthen the quality management of our products and constantly strive to improve the level of service for our clients.

Product

+86-0576-88030503

Tian-shaped Grid Manufacturer

-

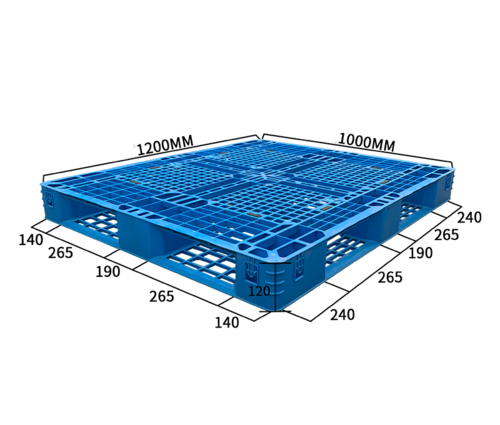

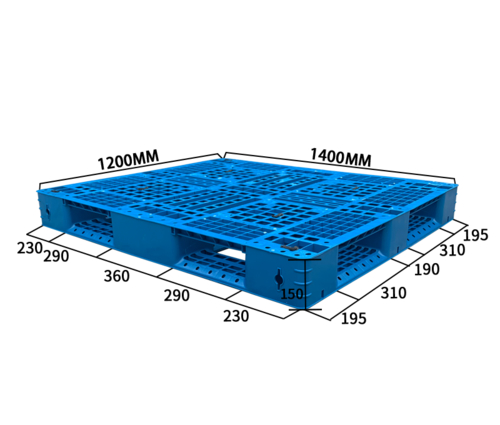

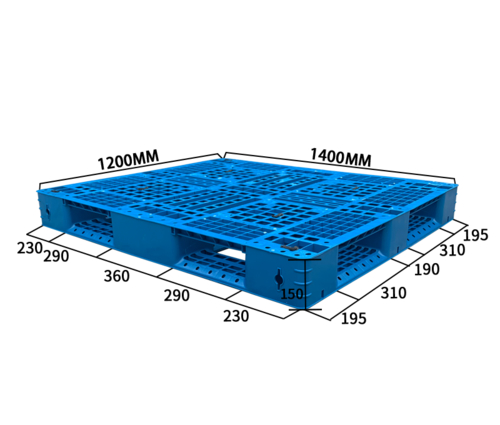

Tian-shaped Grid 1210C (standard) Blue

-

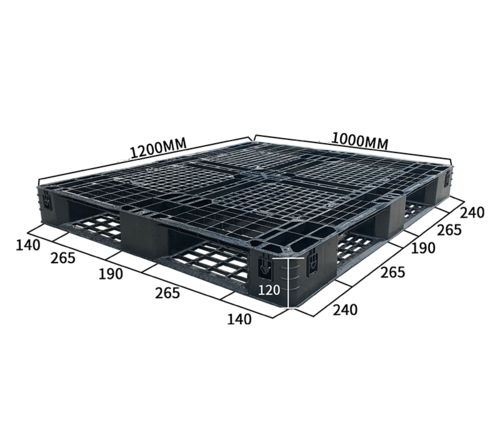

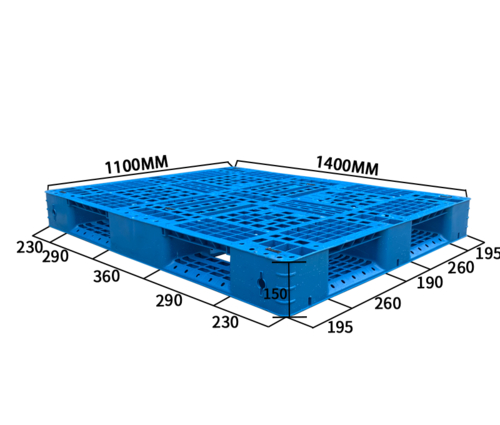

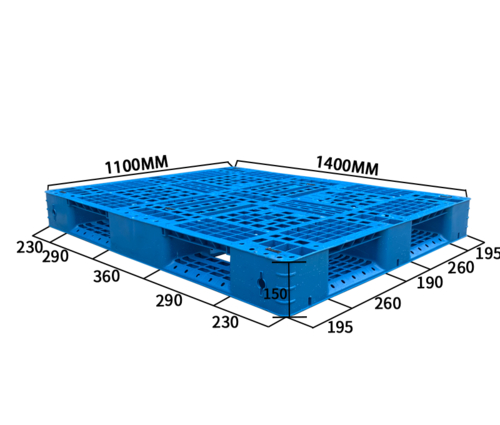

Tian-shaped Grid 1210C (standard) Black

-

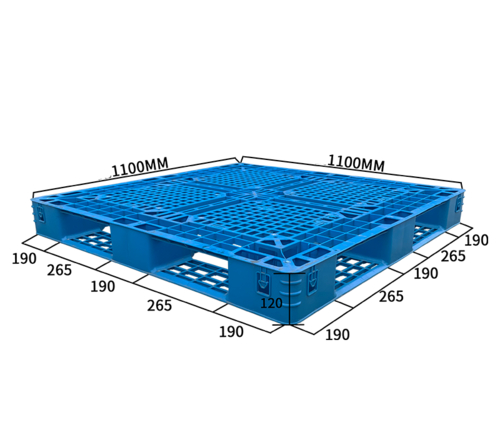

Tian-shaped Grid 1111C (standard) Blue

-

Tian-shaped Grid 1111C (standard) Black

-

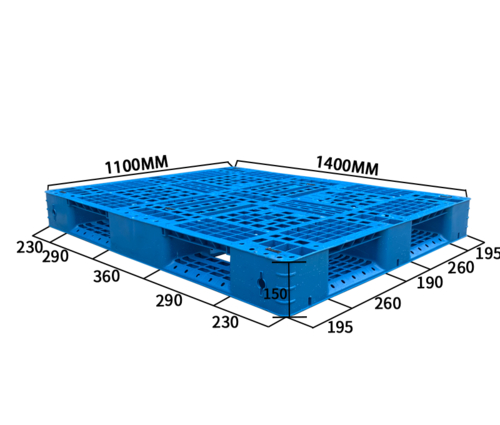

Tian-shaped Grid 1412+7 Steel

-

Tian-shaped Grid 1412+4 Steel

-

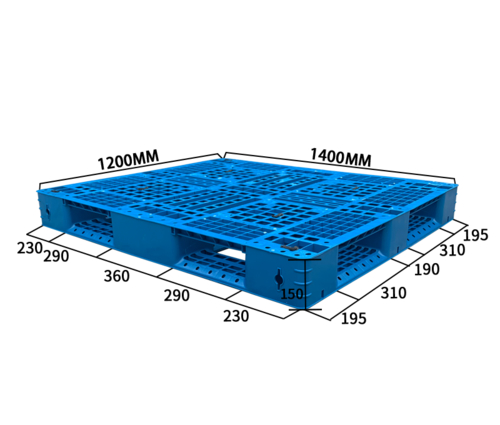

Tian-shaped Grid 1412

-

Tian-shaped Grid 1411+7 Steel

-

Tian-shaped Grid 1411+4 Steel

-

Tian-shaped Grid 1411

-

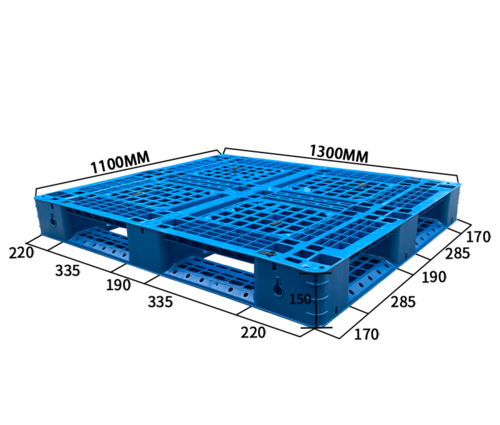

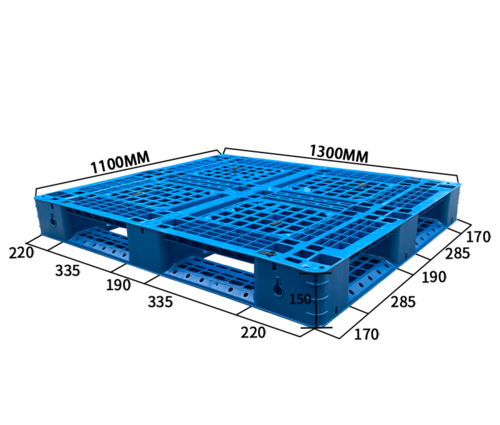

Tian-shaped Grid 1311+6 Steel

-

Tian-shaped Grid 1311+3 Steel

Latest News

-

The role of the built-in steel pipe plastic tray

The main function of the built-in steel pipe in th...

-

Replacing wooden pallets with plastic pallets is the trend of the times

Plastic tray It is the most basic container unit i...

-

Plastic Storage Box Features

Actually, storage is not a huge deal. No matter ho...

-

Maximizing Playroom Space and Organization with a Toy Storage Rack

The Toy Storage Rack RevolutionToy storage racks h...

-

Maximizing Sustainability and Minimizing Waste: The Household Trash Can's Role in a Greener Future

The Evolution of the Household Trash CanThe househ...

-

Square Socks Underwear Storage Box: Organize Your Closet and Simplify Your Life

A cluttered and disorganized closet can be a sourc...

-

Organize Your Beauty Collection with the Three-Tier Drawer Makeup Box: A Comprehensive Guide

In the world of cosmetics and skincare, the allure...

-

The Environmental Impact of Dumping Boxes: A Closer Look at Waste Disposal Practices

Understanding Dumping Boxes:Dumping boxes, also kn...

-

Egg Storage Containers Box: Preserving Freshness and Enhancing Convenience

Eggs are a kitchen staple, versatile in countless ...

-

Cat Ear Desktop Storage Box: Feline Charm Meets Organizational Functionality

Organization meets aesthetics in a delightful fusi...

-

Three Classification Trash Cans: A Sustainable Solution for Waste Management

Waste management is an increasingly critical issue...

-

Organize with Elegance: The Oval Socks Underwear Storage Box

Efficient and aesthetically pleasing organization ...

How has the innovative Tian-shaped Grid plastic tray impacted the logistics and storage industry, and what are its key features and benefits for enhancing efficiency and sustainability?

1. Efficient Use of Space:

The Tian-shaped Grid plastic tray is designed to maximize the efficient use of storage space. Its unique grid pattern allows for precise and secure stacking of goods, which minimizes wasted space within storage facilities and during transportation. This feature directly impacts storage capacity and overall efficiency.

2. Versatility:

One of the standout features of the Tian-shaped Grid plastic tray is its versatility. The grid pattern can be customized to suit various types of products and industries. This adaptability allows companies to use a single type of tray for multiple applications, reducing the need for numerous specialized containers.

3. Durability:

These trays are built to be durable and long-lasting. They can withstand heavy loads and resist wear and tear over time. This durability minimizes the need for frequent replacements, which can lead to cost savings for businesses in terms of both procurement and maintenance.

4. Sustainability:

The logistics and storage industry is increasingly focused on sustainability. Tian-shaped Grid plastic trays align with this trend by being reusable and recyclable. The reduction in waste, coupled with their long lifespan, makes them an eco-friendly alternative to single-use packaging materials.

5. Improved Organization:

The grid pattern on these trays simplifies inventory management and organization. Products are easy to count, sort, and access, which reduces the likelihood of errors and streamlines the overall supply chain process.

6. Enhanced Product Protection:

The trays offer excellent product protection during transportation and storage. The grid pattern provides stability, reducing the risk of product damage or shifting during transit. This is particularly valuable for industries with fragile or sensitive items.

7. Reduction in Handling Time:

Efficient stacking and organization significantly reduce the time and labor required for loading and unloading goods. This translates to quicker turnaround times, cost savings, and improved operational efficiency.

8. Cleaning and Hygiene:

The Tian-shaped Grid plastic tray is easy to clean and maintain, making it suitable for industries with stringent hygiene requirements, such as food and pharmaceuticals. Regular cleaning and sterilization can be done with ease, ensuring product safety and compliance.

9. Reduced Carbon Footprint:

The trays' recyclability, durability, and efficient use of space lead to a reduction in the carbon footprint associated with storage and transportation. Fewer resources are required for production and fewer emissions are generated during logistics operations.

Logistics pallets, often referred to simply as pallets, are essential tools in the world of transportation and material handling.

Design and Structure:

Pallets are typically made of wood, plastic, metal, or composite materials. Wooden pallets are the most common due to their cost-effectiveness and versatility.

They are usually rectangular in shape with top and bottom deck boards, stringers or blocks for support, and often have openings for forklifts or pallet jacks to easily lift and move them.

Standard Sizes:

Pallets come in standard sizes to ensure compatibility with various handling and storage equipment. The most common size is the 48x40-inch pallet in the United States, while the Euro pallet (800x1200mm) is popular in Europe.

Handling and Transportation:

Pallets are designed to be easily moved by forklifts, pallet jacks, or conveyors. They facilitate the efficient loading and unloading of goods, making them a fundamental component of logistics and supply chains.

Pallets can be used for stacking goods, which optimizes storage space in warehouses and during transit.

International Trade:

The use of standardized pallet sizes has become crucial in international trade as it allows for seamless movement of goods across borders. This standardization is essential for container shipping, as containers are often designed to accommodate specific pallet sizes.

Material Variations:

Different materials have their own advantages. Wooden pallets are cost-effective and widely available, but they can be less durable and susceptible to moisture. Plastic pallets are durable and have a longer lifespan but are more expensive. Metal pallets are exceptionally strong but are heavier and more costly.

Pallet Management:

Many companies now engage in pallet management programs to track the movement and condition of pallets. This helps reduce pallet loss and promotes sustainability by ensuring pallets are returned and recycled.

Eco-friendly Practices:

Pallet manufacturers are increasingly using sustainable materials and recycling old pallets. Additionally, there's a growing trend toward using composite materials made from recycled plastics and wood fibers to create eco-friendly pallets.

Customization:

Pallets can be customized to meet specific industry requirements. For example, some pallets have special coatings for use in the food industry, while others are designed for use in industries like pharmaceuticals and chemicals.

Automation Compatibility:

In modern warehouses, automated storage and retrieval systems (AS/RS) often use pallets. These systems can efficiently stack and retrieve goods without human intervention, making pallets a crucial part of advanced logistics.

Safety Considerations:

Proper pallet handling is crucial to prevent accidents and injuries. Training in safe pallet handling and inspection of pallets for damage is essential to maintain safety in logistics operations.

Logistics pallets play a significant role in ensuring the efficient movement of goods across supply chains, making them indispensable in the world of logistics and transportation. Their standardized design, ease of handling, and adaptability to various industries contribute to their widespread use in today's global marketplace.

If you are interested in our products or have any questions, please consult us.

英语

英语

志光证书.jpg?imageView2/2/w/500/h/500/format/jp2/q/100)

志光证书-2.jpg?imageView2/2/w/500/h/500/format/jp2/q/100)

志光证书-3.jpg?imageView2/2/w/500/h/500/format/jp2/q/100)

志光证书-4.jpg?imageView2/2/w/500/h/500/format/jp2/q/100)