Based on the principle of "quality-oriented, customer-driven, honesty essential", as well as the business philosophy of "leading in science and technology, pioneering and innovative, win-win cooperation", we continuously strengthen the quality management of our products and constantly strive to improve the level of service for our clients.

Product

+86-0576-88030503

Blow Molding Double-faced Series Manufacturer

Latest News

-

The role of the built-in steel pipe plastic tray

The main function of the built-in steel pipe in th...

-

Replacing wooden pallets with plastic pallets is the trend of the times

Plastic tray It is the most basic container unit i...

-

Plastic Storage Box Features

Actually, storage is not a huge deal. No matter ho...

-

Maximizing Playroom Space and Organization with a Toy Storage Rack

The Toy Storage Rack RevolutionToy storage racks h...

-

Maximizing Sustainability and Minimizing Waste: The Household Trash Can's Role in a Greener Future

The Evolution of the Household Trash CanThe househ...

-

Square Socks Underwear Storage Box: Organize Your Closet and Simplify Your Life

A cluttered and disorganized closet can be a sourc...

-

Organize Your Beauty Collection with the Three-Tier Drawer Makeup Box: A Comprehensive Guide

In the world of cosmetics and skincare, the allure...

-

The Environmental Impact of Dumping Boxes: A Closer Look at Waste Disposal Practices

Understanding Dumping Boxes:Dumping boxes, also kn...

-

Egg Storage Containers Box: Preserving Freshness and Enhancing Convenience

Eggs are a kitchen staple, versatile in countless ...

-

Cat Ear Desktop Storage Box: Feline Charm Meets Organizational Functionality

Organization meets aesthetics in a delightful fusi...

-

Three Classification Trash Cans: A Sustainable Solution for Waste Management

Waste management is an increasingly critical issue...

-

Organize with Elegance: The Oval Socks Underwear Storage Box

Efficient and aesthetically pleasing organization ...

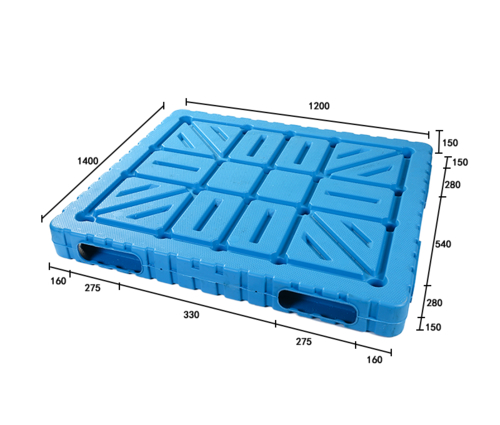

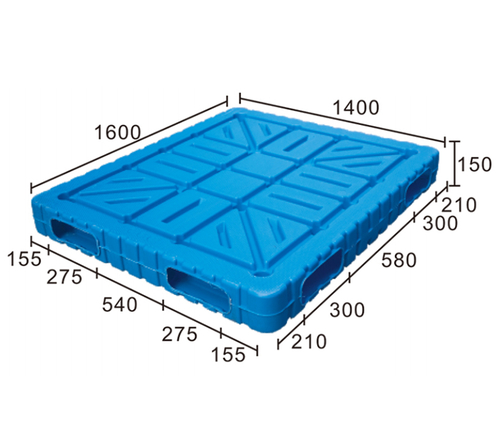

How has the use of Blow Molding Double-faced Series Plastic Pallets transformed the material handling and logistics industry?

1. Durability and Longevity:

Blow molding is a process that creates durable, uniform, and high-strength plastic pallets. The Double-faced Series design adds to the robustness of these pallets, making them capable of withstanding the rigors of modern material handling and transportation. Their extended lifespan compared to traditional wooden pallets minimizes the need for frequent replacements, resulting in cost savings for businesses and reducing the environmental impact associated with pallet disposal.

2. Weight and Size Consistency:

Blow-molded plastic pallets are known for their consistent weight and size, which is critical in standardized supply chain systems. Their uniformity ensures that they can be easily integrated into automated systems and stacked uniformly in racking systems, optimizing warehouse space and improving logistics efficiency.

3. Hygienic and Food-Safe:

For industries like pharmaceuticals, food and beverage, and healthcare, hygiene and sanitation are paramount. Blow Molding Double-faced Series Plastic Pallets are inherently hygienic and resistant to moisture, chemicals, and bacteria. They are easily washable and can meet the stringent requirements for food safety, ensuring the integrity of the products being transported.

4. Sustainability and Eco-friendliness:

One of the most significant contributions of blow-molded plastic pallets to the industry is their positive impact on sustainability. These pallets are typically made from recyclable materials and can be easily recycled at the end of their lifecycle. Additionally, their longer lifespan reduces the need for cutting down trees to make wooden pallets, making them an eco-friendly choice that aligns with the growing emphasis on sustainability in the logistics industry.

5. Weight and Cost Reduction:

The weight of Blow Molding Double-faced Series Plastic Pallets is substantially less than wooden pallets, reducing transportation costs. Lighter pallets also mean less strain on manual labor during loading and unloading, contributing to worker safety and reducing the risk of injury. The weight savings can lead to significant fuel savings for logistics companies, further impacting the bottom line.

6. Consistency in Manufacturing:

Blow molding enables the creation of pallets with consistent dimensions, weight, and strength. This consistency ensures that the pallets perform predictably in automated systems, reducing errors and disruptions in the supply chain. It also simplifies pallet management and inventory tracking, streamlining logistics operations.

7. Customization and Innovation:

Blow Molding Double-faced Series Plastic Pallets can be customized to meet specific industry needs. They can incorporate various features such as anti-slip surfaces, RFID tagging, and unique designs to accommodate specific product requirements. This level of customization fosters innovation, allowing companies to adapt their pallets to evolving logistics challenges.

8. Compliance with International Regulations:

The use of plastic pallets, especially in international trade, can facilitate compliance with various regulations and standards. Many countries have stringent rules concerning the use of wooden pallets due to the risk of pests and contamination. Plastic pallets, particularly those designed for export, are exempt from these regulations, simplifying global supply chain logistics.

How Does Blow Molding Double-faced Series Plastic Pallets Revolutionize Material Handling and Logistics?

Durability and Longevity: Blow molding double-faced plastic pallets are incredibly durable and long-lasting. They are designed to withstand the rigors of transportation, storage, and handling. Unlike wooden pallets that can splinter or break and traditional injection-molded plastic pallets that can crack, these pallets are less prone to damage. This enhanced longevity leads to cost savings over time as there is less need for replacement.

Consistent Quality: The blow molding process allows for the production of plastic pallets with consistent quality and dimensions. This uniformity is crucial in the logistics and supply chain industry, where pallet dimensions need to be standardized for efficient storage and transportation. Companies can depend on these pallets to fit their requirements precisely.

Hygienic and Easy to Clean: Blow molded plastic pallets are ideal for industries with stringent hygiene requirements, such as the food and pharmaceutical industries. They are easy to clean, resistant to moisture, and do not harbor pests or bacteria, unlike wooden pallets, which can be challenging to sanitize. This makes them an excellent choice for environments where cleanliness is a top priority.

Lightweight and Easy Handling: Despite their durability, blow molded plastic pallets are relatively lightweight, making them easier to handle than traditional wooden pallets. This lightweight feature contributes to improved worker safety and ease of use. Moreover, these pallets are often designed with ergonomic features such as handholds and anti-slip surfaces, further enhancing their handling efficiency.

Environmental Sustainability: Blow molding double-faced plastic pallets are often made from recyclable materials, and they are themselves recyclable. This sustainability aspect aligns with the growing environmental concerns in the industry, as companies strive to reduce their carbon footprint and adopt eco-friendly solutions.

Customization: Manufacturers can easily customize blow molded plastic pallets to meet the specific needs of their products and processes. This flexibility allows businesses to optimize their material handling systems, whether for specialized goods or unique storage requirements.

Cost Efficiency: While the initial investment in blow molded plastic pallets may be higher than wooden pallets, the long-term cost efficiency is evident. Their durability, reusability, and reduced maintenance costs contribute to significant savings over time. Additionally, these pallets often have a lower total cost of ownership when compared to other materials.

International Shipping Compliance: Blow molded plastic pallets are ISPM-15 compliant, which means they can be used for international shipments without the need for heat treatment or fumigation, as is often required for wooden pallets. This simplifies the logistics of global supply chains.

Stacking and Nesting Capabilities: Blow molded plastic pallets are designed to stack and nest efficiently. They can be nested together to save space when not in use, and they stack securely when loaded. This feature optimizes storage and transportation capacity, ultimately reducing storage costs and space requirements.

If you are interested in our products or have any questions, please consult us.

英语

英语

志光证书.jpg?imageView2/2/w/500/h/500/format/jp2/q/100)

志光证书-2.jpg?imageView2/2/w/500/h/500/format/jp2/q/100)

志光证书-3.jpg?imageView2/2/w/500/h/500/format/jp2/q/100)

志光证书-4.jpg?imageView2/2/w/500/h/500/format/jp2/q/100)