Based on the principle of "quality-oriented, customer-driven, honesty essential", as well as the business philosophy of "leading in science and technology, pioneering and innovative, win-win cooperation", we continuously strengthen the quality management of our products and constantly strive to improve the level of service for our clients.

Product

+86-0576-88030503

Plastic Tray Manufacturer

-

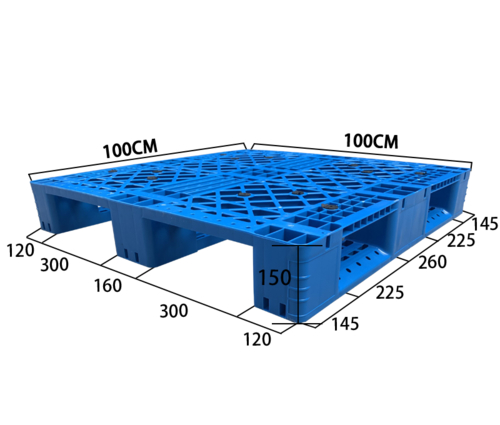

Chuan-shaped Grid Plastic Tray 1010+10 Steel Pipes

-

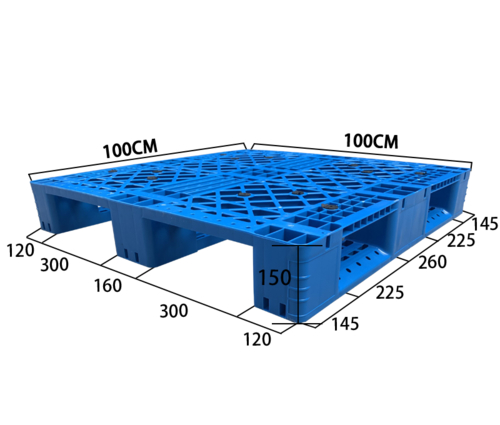

Chuan-shaped Grid Plastic Tray 1010+4 Steel Pipes

-

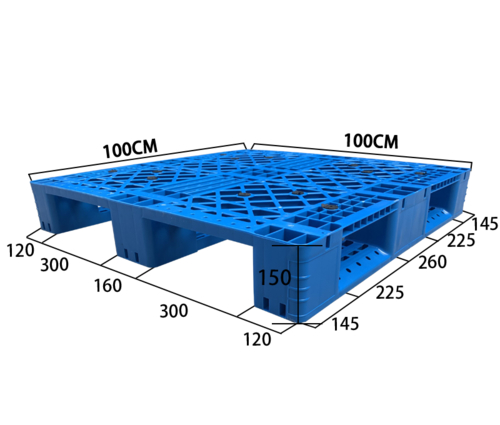

Chuan-shaped Grid Plastic Tray 1010

-

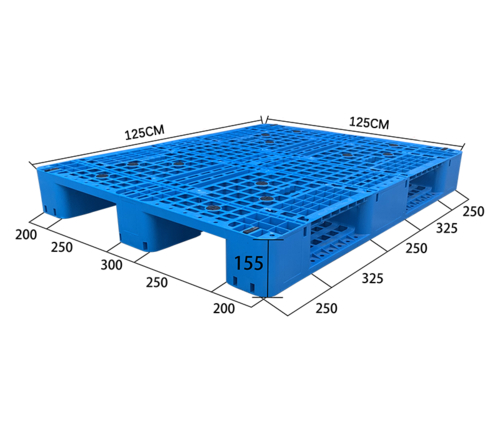

Grid Chuanzi Plastic Tray Tobacco Special 125.100

-

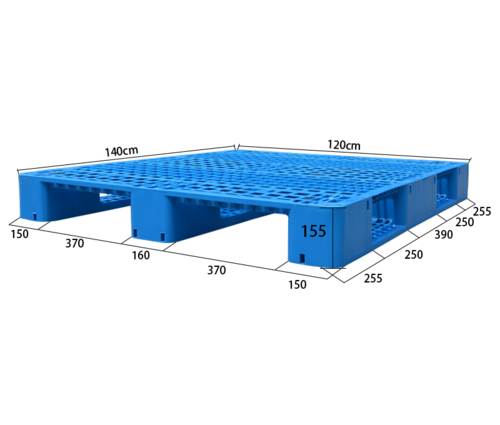

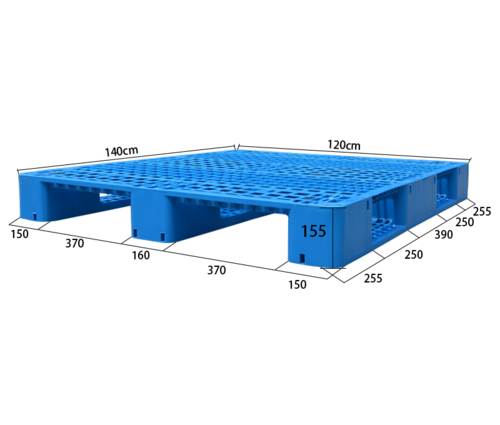

Chuan-shaped Grid Plastic Tray 1412 (8 Steel Pipes)

-

Chuan-shaped Grid Plastic Tray 1412 (4 Steel Pipes)

-

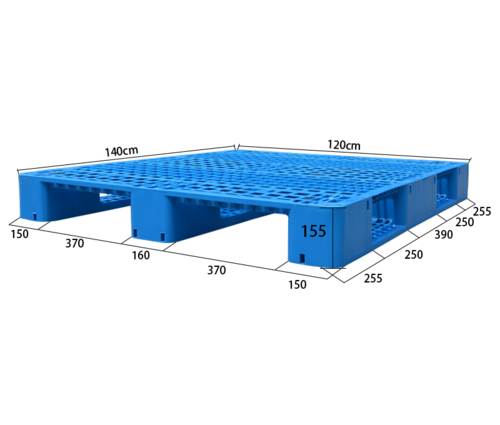

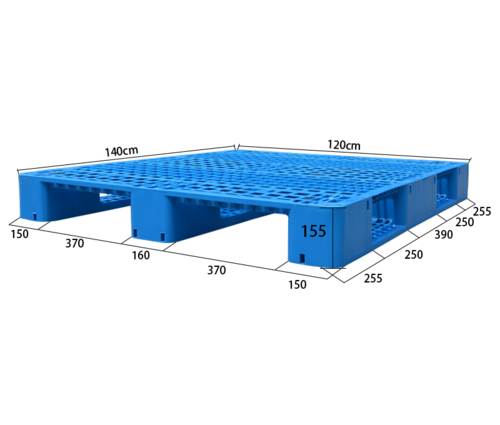

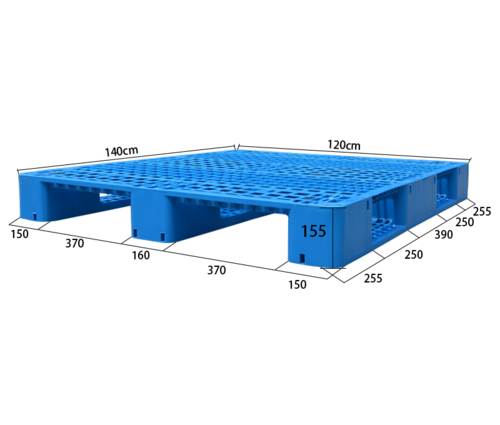

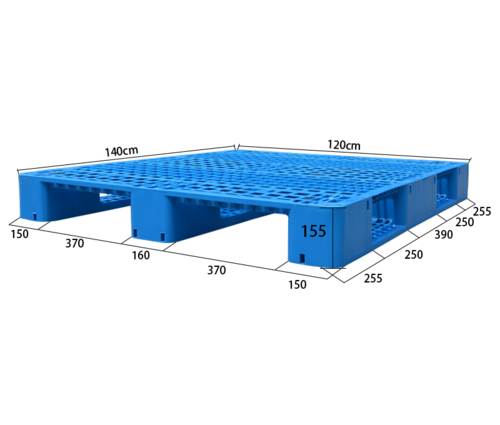

Chuan-shaped Grid Plastic Tray 1412 (Without Steel Pipe)

-

Chuan-shaped Grid Plastic Tray 1311 (8 Steel Pipes)

-

Grid Sichuan Plastic Tray 1311 (4 Steel)

-

Chuan-shaped Grid Plastic Tray 1311 (Without Steel Pipe)

-

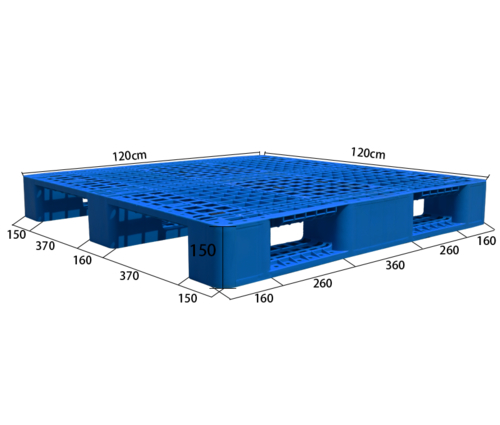

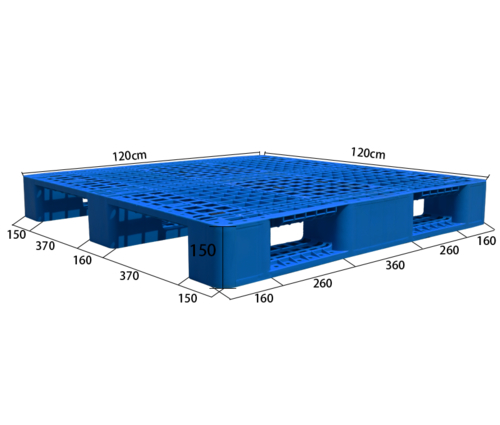

Chuan-shaped Grid Plastic Tray 1212 (8 Steel Pipes)

-

Grid Sichuan Plastic Tray 1212 (4 Steel)

Latest News

-

The role of the built-in steel pipe plastic tray

The main function of the built-in steel pipe in th...

-

Replacing wooden pallets with plastic pallets is the trend of the times

Plastic tray It is the most basic container unit i...

-

Plastic Storage Box Features

Actually, storage is not a huge deal. No matter ho...

-

Maximizing Playroom Space and Organization with a Toy Storage Rack

The Toy Storage Rack RevolutionToy storage racks h...

-

Maximizing Sustainability and Minimizing Waste: The Household Trash Can's Role in a Greener Future

The Evolution of the Household Trash CanThe househ...

-

Square Socks Underwear Storage Box: Organize Your Closet and Simplify Your Life

A cluttered and disorganized closet can be a sourc...

-

Organize Your Beauty Collection with the Three-Tier Drawer Makeup Box: A Comprehensive Guide

In the world of cosmetics and skincare, the allure...

-

The Environmental Impact of Dumping Boxes: A Closer Look at Waste Disposal Practices

Understanding Dumping Boxes:Dumping boxes, also kn...

-

Egg Storage Containers Box: Preserving Freshness and Enhancing Convenience

Eggs are a kitchen staple, versatile in countless ...

-

Cat Ear Desktop Storage Box: Feline Charm Meets Organizational Functionality

Organization meets aesthetics in a delightful fusi...

-

Three Classification Trash Cans: A Sustainable Solution for Waste Management

Waste management is an increasingly critical issue...

-

Organize with Elegance: The Oval Socks Underwear Storage Box

Efficient and aesthetically pleasing organization ...

How is the plastic tray industry evolving to meet environmental and sustainability concerns?

1. Material Innovation:

One of the most significant shifts in the plastic tray industry has been the development of sustainable materials. Manufacturers have been investing in research to create biodegradable and compostable plastic trays made from materials such as PLA (polylactic acid), sugarcane, or recycled plastics. These trays maintain the necessary durability while having a significantly reduced environmental impact.

2. Recycling and Reusability:

In an effort to reduce the amount of plastic waste generated, manufacturers are designing plastic trays that are easily recyclable or reusable. Some companies are working on developing closed-loop systems where trays are collected, cleaned, and reused within their supply chains. This approach helps to reduce the demand for virgin plastic and lower the industry's overall carbon footprint.

3. Lightweighting and Material Reduction:

Efforts are also being made to reduce the material used in plastic trays while maintaining their strength and functionality. Lightweighting not only reduces the consumption of raw materials but also decreases energy usage during production and transportation.

4. Eco-Friendly Production Processes:

Manufacturers are increasingly adopting more sustainable production methods. These include energy-efficient machinery, reduced water consumption, and the use of renewable energy sources in their facilities, which contribute to a lower overall environmental impact.

5. Extended Producer Responsibility (EPR):

Many regions and countries have implemented EPR programs that hold manufacturers responsible for the entire life cycle of their products, including post-consumer waste management. This has incentivized the plastic tray industry to invest in recycling and waste management programs.

6. Consumer Education and Behavior Change:

Educating consumers on the proper disposal and recycling of plastic trays and encouraging sustainable behavior has become a priority. Improved labeling and public awareness campaigns aim to minimize littering and promote responsible plastic tray disposal.

7. Regulatory Compliance:

Governments and regulatory bodies are increasingly implementing stricter regulations on plastic usage and waste management. The industry is adjusting to meet these standards and often goes beyond compliance to demonstrate its commitment to sustainability.

8. Collaborative Initiatives:

The plastic tray industry is actively engaging in partnerships with environmental organizations, governments, and other stakeholders to find common ground and collaborate on sustainable solutions. These collaborations often lead to innovative approaches and best practices.

How are plastic trays revolutionizing the food packaging industry, and what advantages do they offer over traditional packaging methods?

1. Improved Product Presentation:

Plastic trays provide an excellent platform for showcasing food products. They come in various shapes and sizes, allowing food manufacturers to present their items attractively. Transparent plastic trays, in particular, offer a clear view of the product, enticing customers with its freshness and quality. The visual appeal is a crucial factor in attracting consumers, and plastic trays excel in this regard.

2. Enhanced Product Protection:

Plastic trays offer superior protection for food items. They are designed to be sturdy and durable, preventing damage during transportation and storage. This durability ensures that the product arrives at its destination in the same condition it left the manufacturer, reducing waste and customer complaints.

3. Extended Shelf Life:

Plastic trays are often used in conjunction with other packaging technologies like vacuum sealing, modified atmosphere packaging (MAP), and hermetic sealing. These methods help extend the shelf life of food products by preventing spoilage, microbial growth, and oxidation. As a result, food stays fresher for longer, reducing food waste and benefiting both manufacturers and consumers.

4. Versatility and Customization:

Plastic trays are highly versatile and can be customized to suit different food types and packaging requirements. Manufacturers can choose the appropriate material, size, and design to meet the specific needs of their products. Whether it's for deli meats, baked goods, or fresh produce, plastic trays can be adapted to fit various applications.

5. Convenient Handling and Portion Control:

Plastic trays are designed for easy handling and portion control. They often feature compartments and dividers, allowing precise measurement and packaging of food items. This is especially advantageous in the foodservice industry, where consistent portion sizes are critical for cost control and customer satisfaction.

6. Sustainable Options:

Sustainability is a growing concern in the food packaging industry. Plastic trays are evolving to offer more environmentally friendly alternatives. Manufacturers are developing trays made from recyclable and biodegradable materials, reducing their environmental footprint. Furthermore, the improved shelf life of products in plastic trays can reduce food waste, which is a significant contributor to environmental problems.

7. Cost Efficiency:

Plastic trays are cost-effective packaging solutions. They are often lighter than alternative materials like glass or metal, reducing transportation costs. Additionally, their durability ensures that fewer products are damaged in transit, saving both manufacturers and retailers money.

8. Food Safety and Hygiene:

Plastic trays meet rigorous food safety standards. They are non-reactive and do not contaminate the food they hold. Many plastic trays are also designed for easy cleaning and disinfection, further enhancing food safety and reducing the risk of foodborne illnesses.

9. Branding and Marketing Opportunities:

Customizable plastic trays offer branding opportunities for food companies. The packaging can be printed with logos, branding messages, and product information, effectively conveying a brand's identity and story to consumers.

If you are interested in our products or have any questions, please consult us.

英语

英语

志光证书.jpg?imageView2/2/w/500/h/500/format/jp2/q/100)

志光证书-2.jpg?imageView2/2/w/500/h/500/format/jp2/q/100)

志光证书-3.jpg?imageView2/2/w/500/h/500/format/jp2/q/100)

志光证书-4.jpg?imageView2/2/w/500/h/500/format/jp2/q/100)