Based on the principle of "quality-oriented, customer-driven, honesty essential", as well as the business philosophy of "leading in science and technology, pioneering and innovative, win-win cooperation", we continuously strengthen the quality management of our products and constantly strive to improve the level of service for our clients.

Product

+86-0576-88030503

Nine Feet Blow Molding Series Manufacturer

-

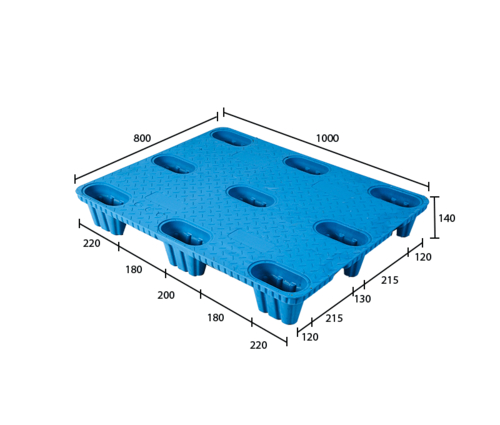

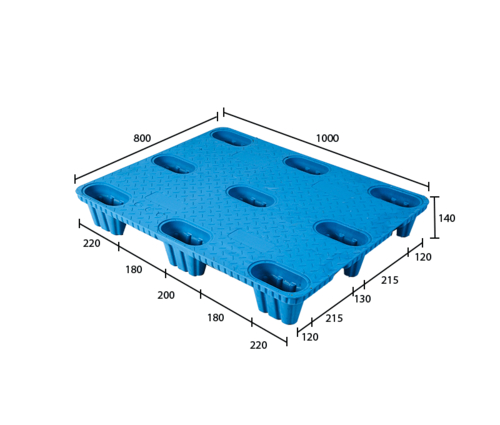

1008A Nine Feet Blow Molding

-

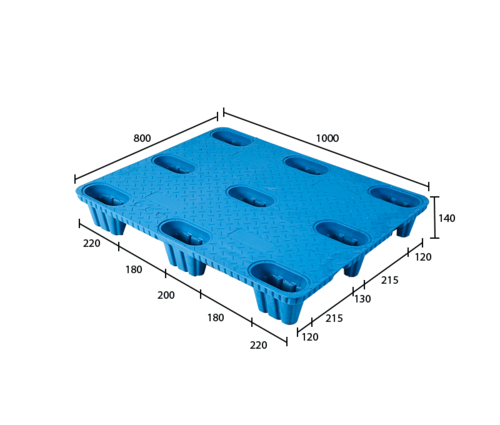

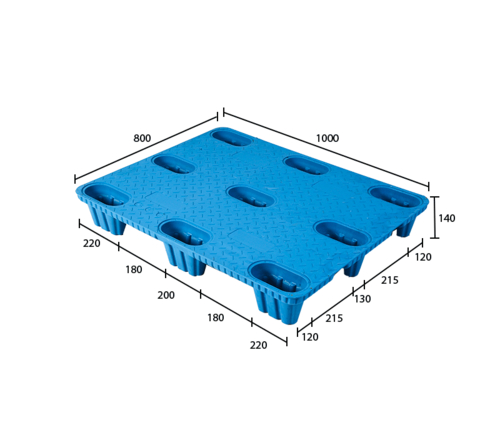

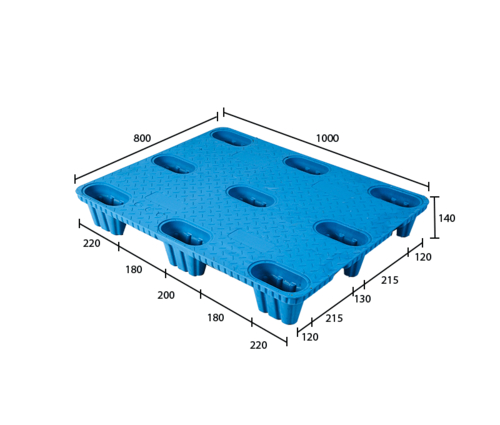

1008B Nine Feet Blow Molding

-

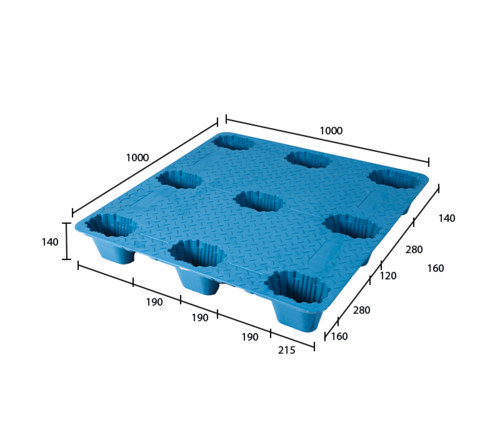

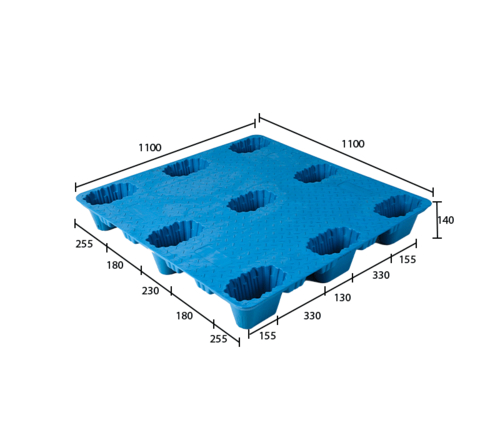

1010A Nine Feet Blow Molding

-

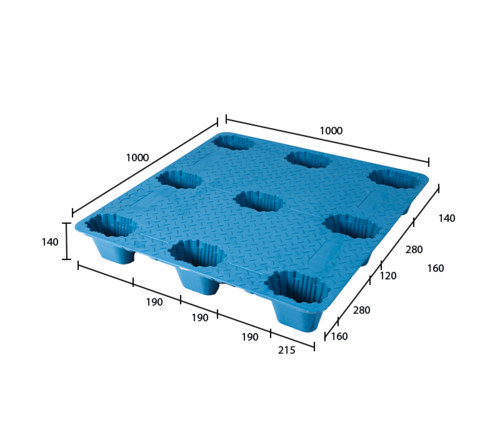

1010B Nine Feet Blow Molding

-

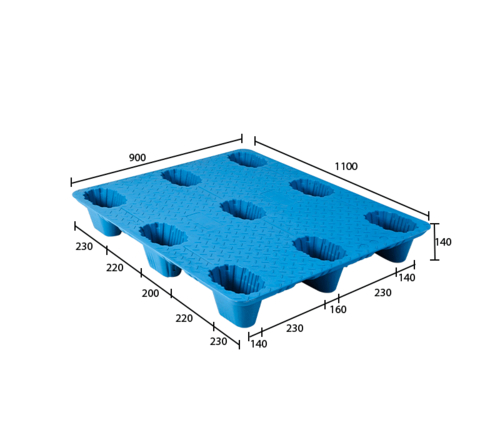

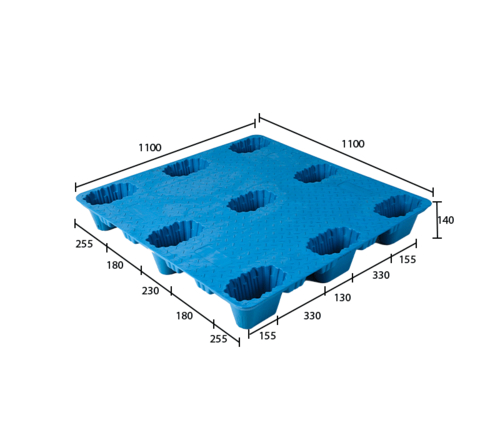

1109A Nine Feet Blow Molding

-

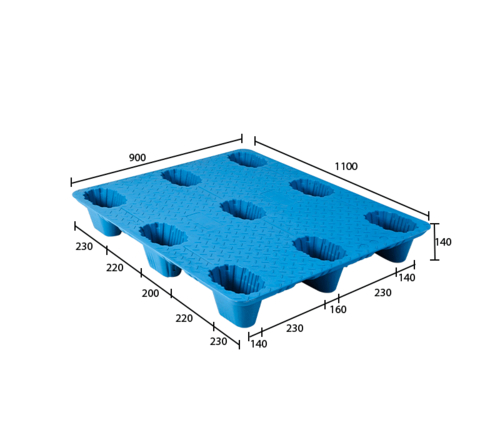

1109B Nine Feet Blow Molding

-

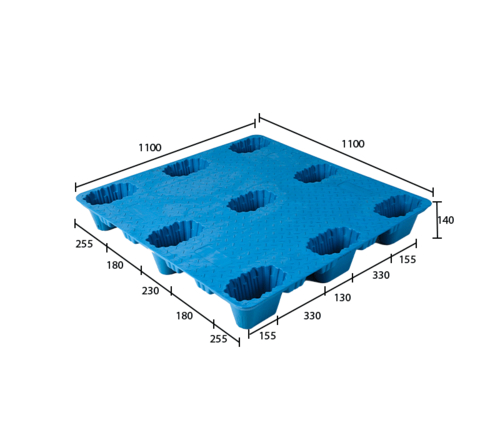

1111A Nine Feet Blow Molding

-

1111B Nine Feet Blow Molding

-

1111C Nine Feet Blow Molding

-

1111D Nine Feet Blow Molding

-

1111E Nine Feet Blow Molding

-

1111F Nine Feet Blow Molding

Latest News

-

The role of the built-in steel pipe plastic tray

The main function of the built-in steel pipe in th...

-

Replacing wooden pallets with plastic pallets is the trend of the times

Plastic tray It is the most basic container unit i...

-

Plastic Storage Box Features

Actually, storage is not a huge deal. No matter ho...

-

Maximizing Playroom Space and Organization with a Toy Storage Rack

The Toy Storage Rack RevolutionToy storage racks h...

-

Maximizing Sustainability and Minimizing Waste: The Household Trash Can's Role in a Greener Future

The Evolution of the Household Trash CanThe househ...

-

Square Socks Underwear Storage Box: Organize Your Closet and Simplify Your Life

A cluttered and disorganized closet can be a sourc...

-

Organize Your Beauty Collection with the Three-Tier Drawer Makeup Box: A Comprehensive Guide

In the world of cosmetics and skincare, the allure...

-

The Environmental Impact of Dumping Boxes: A Closer Look at Waste Disposal Practices

Understanding Dumping Boxes:Dumping boxes, also kn...

-

Egg Storage Containers Box: Preserving Freshness and Enhancing Convenience

Eggs are a kitchen staple, versatile in countless ...

-

Cat Ear Desktop Storage Box: Feline Charm Meets Organizational Functionality

Organization meets aesthetics in a delightful fusi...

-

Three Classification Trash Cans: A Sustainable Solution for Waste Management

Waste management is an increasingly critical issue...

-

Organize with Elegance: The Oval Socks Underwear Storage Box

Efficient and aesthetically pleasing organization ...

How are Nine Feet Blow Molding Series Plastic Pallets Transforming the Shipping and Packaging Industry?

Efficient Use of Space

One of the standout features of Nine Feet Blow Molding Series Plastic Pallets is their ability to efficiently use space during shipping and storage. The nine strategically placed feet provide optimal support for the pallet, enabling it to evenly distribute weight and stack more uniformly than traditional pallets. This design reduces wasted space, allowing businesses to maximize the number of products they can store and transport within the same area.

Consistent Dimensions

These plastic pallets are manufactured with consistent dimensions, offering an advantage in the highly precise and automated shipping and packaging industry. Uniformity in size ensures that Nine Feet Blow Molding Series Plastic Pallets can be easily integrated into automated systems, such as conveyor belts, palletizers, and packaging machines. This reduces handling time, minimizes the margin for error, and ultimately increases operational efficiency.

Durability for Extended Use

Shipping and packaging operations are demanding and can be hard on equipment. Wooden pallets are susceptible to splintering and moisture damage, while metal pallets can corrode. Nine Feet Blow Molding Series Plastic Pallets are designed to withstand the rigors of shipping and storage, including exposure to various environmental conditions and heavy loads. Their durability ensures a longer service life, reducing the need for frequent replacements.

Hygienic and Safe

Maintaining a sanitary environment during shipping and packaging is crucial, particularly in industries like food and pharmaceuticals. Traditional pallets, especially wooden ones, can be problematic as they may harbor contaminants and pests. In contrast, Nine Feet Blow Molding Series Plastic Pallets are easy to clean and do not absorb liquids, providing an excellent option for maintaining hygiene and safety standards. Moreover, their lightweight design reduces the risk of workplace injuries when handling and moving pallets.

Sustainability and Reduced Environmental Impact

Sustainability has become a central focus in the shipping and packaging industry. Nine Feet Blow Molding Series Plastic Pallets are often made from recycled materials and can be recycled at the end of their lifecycle. Their lightweight design also contributes to reduced transportation emissions, aligning with the industry's growing commitment to environmental responsibility.

Customization for Diverse Needs

Different businesses have varying shipping and packaging requirements, and these plastic pallets offer customization options to meet these needs. They can be tailored to specific sizes, shapes, and load capacities, allowing businesses to optimize their shipping and packaging processes. Whether it's delicate items or heavy equipment, these plastic pallets are versatile enough to accommodate diverse needs.

Nine Feet Blow Molding Series Plastic Pallets are revolutionizing the shipping and packaging industry in several ways. Their efficient use of space, consistent dimensions, durability, and customization options make them a versatile and cost-effective choice for businesses. Their impact on hygiene and safety standards is significant, especially in industries with stringent regulations. Furthermore, their role in promoting sustainability aligns with the industry's growing emphasis on environmental responsibility. The introduction of these pallets has paved the way for more efficient and sustainable shipping and packaging processes, reducing costs and improving overall productivity. As the demand for smarter, more efficient, and eco-friendly shipping and packaging solutions continues to grow, Nine Feet Blow Molding Series Plastic Pallets are positioned to play a central role in shaping the future of the industry.

How Are Nine Feet Blow Molding Series Plastic Pallets Revolutionizing Supply Chain Efficiency?

Optimal Space Utilization

One of the standout features of Nine Feet Blow Molding Series Plastic Pallets is their unique design, which incorporates nine strategically placed feet. This design provides optimal support for the pallet, enabling it to distribute weight more evenly and stack uniformly. Unlike traditional pallets, which often leave gaps or wasted space between loads, these plastic pallets maximize storage and transportation space. This efficiency is critical in the supply chain industry, where every square inch counts.

Standardized Dimensions

The consistency in size and shape of Nine Feet Blow Molding Series Plastic Pallets is a significant advantage in supply chain operations. Standardized dimensions ensure that these pallets seamlessly integrate with various automated systems such as conveyor belts, robotic arms, and automated storage and retrieval systems. This consistency reduces handling time, minimizes errors, and ultimately boosts operational efficiency.

Durability for Heavy Loads

Supply chain operations frequently involve the movement and transportation of heavy loads. Traditional wooden pallets can splinter, warp, and fail under extreme weight, while metal pallets can corrode. Nine Feet Blow Molding Series Plastic Pallets are engineered to withstand heavy loads and harsh conditions. They maintain their structural integrity, reducing the need for frequent replacements and repairs, ultimately saving businesses time and money.

Hygiene and Safety Standards

Maintaining a clean and safe environment is a top priority in the supply chain industry, especially in sectors like food, pharmaceuticals, and electronics. Traditional pallets, particularly wooden ones, can pose a risk by harboring contaminants and pests. In contrast, these plastic pallets are easy to clean and do not absorb liquids, making them an ideal choice for industries with stringent hygiene requirements. Their lightweight design also minimizes the risk of workplace injuries during pallet handling.

Sustainability and Environmental Responsibility

Sustainability is a growing focus in supply chain management. Nine Feet Blow Molding Series Plastic Pallets are often made from recycled materials and are fully recyclable at the end of their lifecycle. Their lightweight design also reduces transportation emissions, contributing to the industry's commitment to reducing its environmental footprint.

Customization for Diverse Needs

Supply chain operations can vary greatly between industries and businesses. Nine Feet Blow Molding Series Plastic Pallets offer customization options to meet these diverse needs. They can be tailored to specific sizes, shapes, and load capacities, ensuring that they are adaptable to a wide range of products and materials. This flexibility allows businesses to optimize their supply chain operations.

Nine Feet Blow Molding Series Plastic Pallets are transforming supply chain efficiency in multiple ways. Their ability to maximize space utilization, standardized dimensions, durability, and customization options make them an adaptable and cost-effective choice for businesses. Their role in maintaining hygiene and safety standards is critical, particularly in highly regulated industries. Furthermore, their commitment to sustainability aligns with the industry's growing emphasis on environmental responsibility. The introduction of these pallets has opened doors to more efficient and sustainable supply chain processes, reducing costs and enhancing overall productivity. As the demand for smarter, more efficient, and eco-friendly supply chain solutions continues to grow, Nine Feet Blow Molding Series Plastic Pallets are poised to be a central element in shaping the future of the industry.

If you are interested in our products or have any questions, please consult us.

英语

英语

志光证书.jpg?imageView2/2/w/500/h/500/format/jp2/q/100)

志光证书-2.jpg?imageView2/2/w/500/h/500/format/jp2/q/100)

志光证书-3.jpg?imageView2/2/w/500/h/500/format/jp2/q/100)

志光证书-4.jpg?imageView2/2/w/500/h/500/format/jp2/q/100)