Based on the principle of "quality-oriented, customer-driven, honesty essential", as well as the business philosophy of "leading in science and technology, pioneering and innovative, win-win cooperation", we continuously strengthen the quality management of our products and constantly strive to improve the level of service for our clients.

Product

+86-0576-88030503

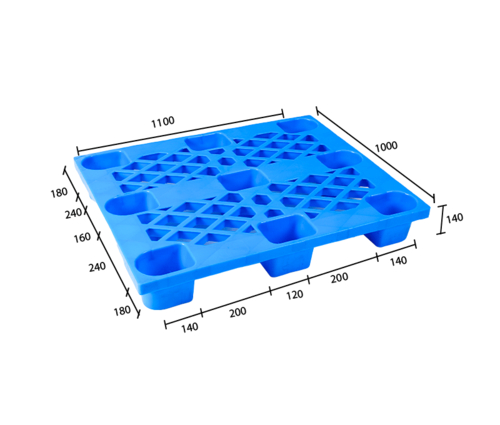

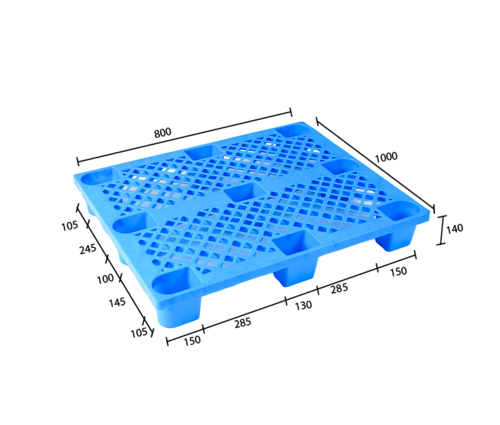

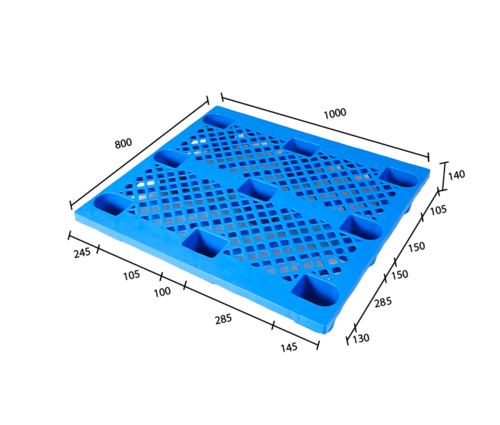

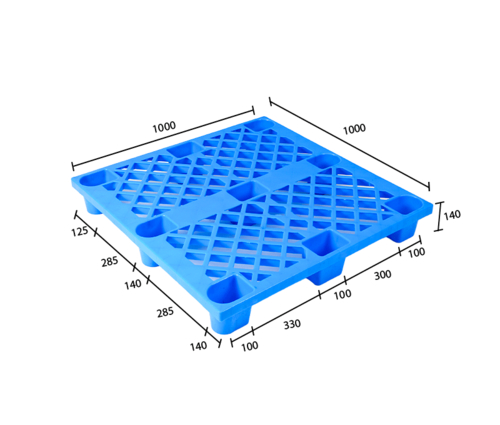

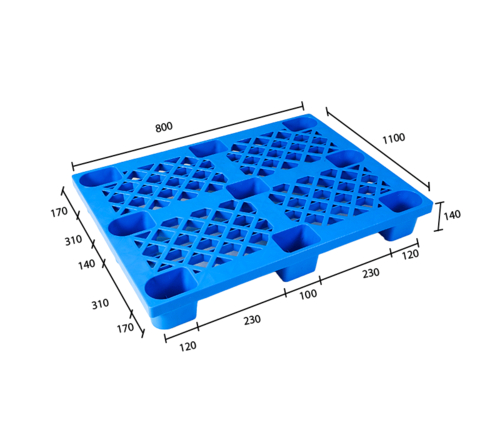

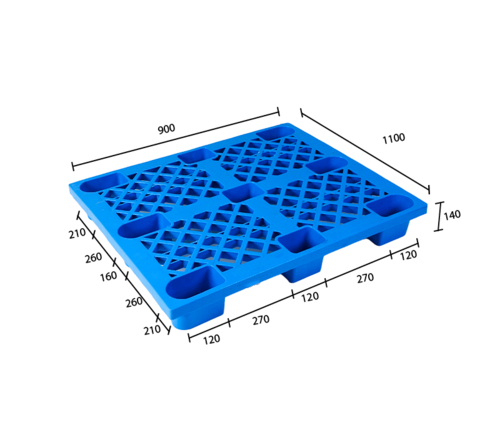

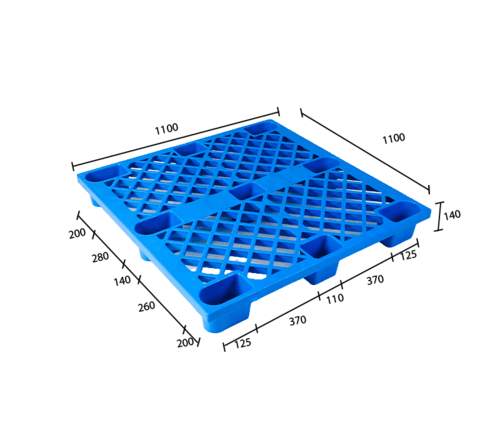

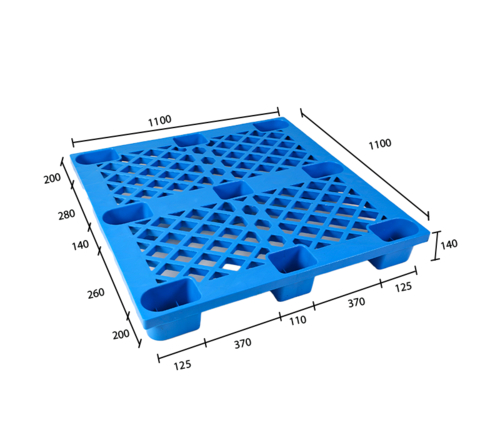

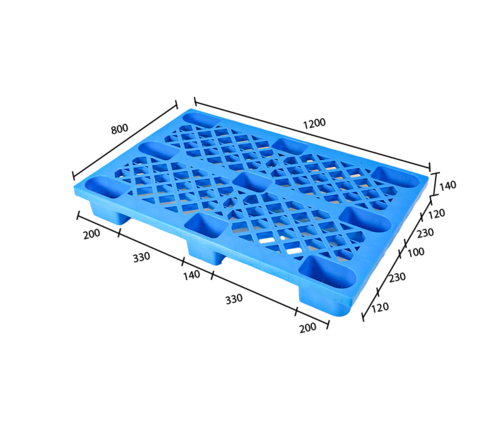

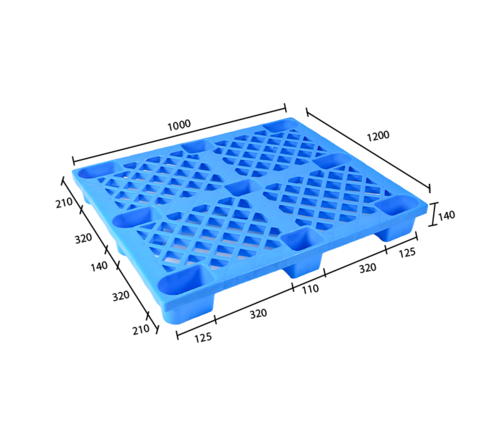

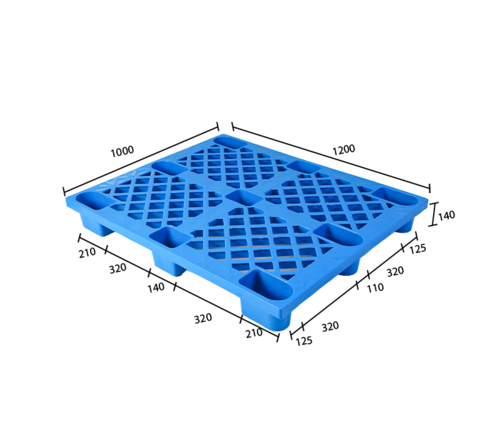

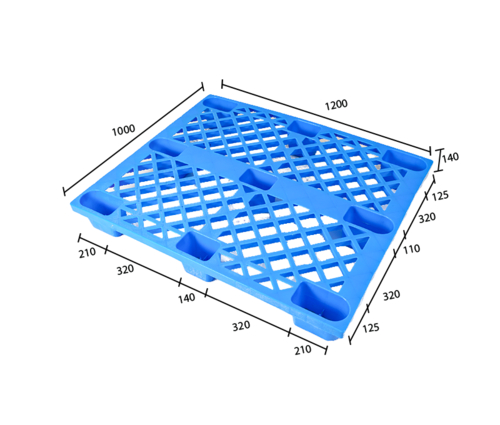

Single-Faced Grid Nine Feet Manufacturer

Latest News

-

The role of the built-in steel pipe plastic tray

The main function of the built-in steel pipe in th...

-

Replacing wooden pallets with plastic pallets is the trend of the times

Plastic tray It is the most basic container unit i...

-

Plastic Storage Box Features

Actually, storage is not a huge deal. No matter ho...

-

Maximizing Playroom Space and Organization with a Toy Storage Rack

The Toy Storage Rack RevolutionToy storage racks h...

-

Maximizing Sustainability and Minimizing Waste: The Household Trash Can's Role in a Greener Future

The Evolution of the Household Trash CanThe househ...

-

Square Socks Underwear Storage Box: Organize Your Closet and Simplify Your Life

A cluttered and disorganized closet can be a sourc...

-

Organize Your Beauty Collection with the Three-Tier Drawer Makeup Box: A Comprehensive Guide

In the world of cosmetics and skincare, the allure...

-

The Environmental Impact of Dumping Boxes: A Closer Look at Waste Disposal Practices

Understanding Dumping Boxes:Dumping boxes, also kn...

-

Egg Storage Containers Box: Preserving Freshness and Enhancing Convenience

Eggs are a kitchen staple, versatile in countless ...

-

Cat Ear Desktop Storage Box: Feline Charm Meets Organizational Functionality

Organization meets aesthetics in a delightful fusi...

-

Three Classification Trash Cans: A Sustainable Solution for Waste Management

Waste management is an increasingly critical issue...

-

Organize with Elegance: The Oval Socks Underwear Storage Box

Efficient and aesthetically pleasing organization ...

The Versatile Role of Single-Faced Grid Nine Feet Plastic Trays in Modern Logistics

Material Handling and Logistics: An Industry Overview

Material handling and logistics are critical components of many industries, ranging from manufacturing and retail to healthcare and agriculture. Efficient material handling can significantly impact cost reduction, lead time reduction, and overall operational efficiency.

The Role of Single-Faced Grid Nine Feet Plastic Trays

The Single-Faced Grid Nine Feet Plastic Tray is a versatile solution to various material handling challenges. Here are some key roles it plays in different industries:

Manufacturing Industry: In manufacturing, these trays are used to transport parts and components from one workstation to another. They are stackable and designed to fit efficiently within conveyor systems, allowing for a continuous and organized production process.

Warehousing and Distribution: These trays are valuable in warehousing and distribution centers. They can hold various products, and their grid design ensures that items remain stable during transportation, reducing the risk of damage and ensuring ease of stacking in racks.

Retail Sector: In the retail industry, these trays are utilized for product display and organization. They are particularly useful in supermarkets and large stores, where they help in categorizing products, optimizing space, and simplifying restocking processes.

Agriculture and Food Industry: In agriculture, these trays are ideal for transporting produce, and in the food industry, they are used for the storage and movement of food items. The grid design is particularly helpful for maintaining airflow around products, which is crucial for certain perishables.

Healthcare: In hospitals and healthcare facilities, these trays can be used for organizing and transporting medical supplies and equipment, contributing to the overall efficiency of patient care.

Advantages and Impact

The Single-Faced Grid Nine Feet Plastic Tray offers numerous advantages that have a significant impact on various industries:

Durability: These trays are made of robust plastic materials, ensuring a long lifespan and cost-effectiveness.

Stackability: The trays are designed for easy stacking, saving space in warehouses and facilitating efficient storage.

Hygiene: In industries where cleanliness is crucial, the plastic material is easy to clean and sanitize.

Customization: They can be customized to meet specific industry needs, such as size, load-bearing capacity, and color coding for product differentiation.

Challenges and Sustainability

While these trays offer many advantages, it's essential to consider sustainability and environmental impact. Manufacturers and industries are increasingly exploring eco-friendly alternatives, including recyclable materials and reusable designs. Finding a balance between functionality and sustainability is an ongoing challenge in material handling.

the Single-Faced Grid Nine Feet Plastic Tray has proven to be an invaluable tool in material handling and logistics across a range of industries. Its versatility, durability, and efficiency make it an essential component of modern supply chains, improving efficiency and streamlining operations. However, as industries increasingly prioritize sustainability, there is a growing emphasis on developing eco-friendly alternatives to address environmental concerns.

The Single-Faced Grid Nine Feet Plastic Tray in the Logistics Industry: Efficiency and Sustainability

What is a Single-Faced Grid Nine Feet Plastic Tray?

A Single-Faced Grid Nine Feet Plastic Tray is a pallet-like item designed for material handling and storage within the logistics industry. It is typically made of high-quality plastic, providing durability, and is designed with a grid pattern on one side to enhance stability and reduce slippage during transport. Measuring approximately nine square feet, this tray is known for its versatility and compatibility with various handling equipment.

Efficiency in Material Handling

One of the primary benefits of using Single-Faced Grid Nine Feet Plastic Trays is the enhancement of efficiency in material handling. These trays are designed to facilitate easy loading and unloading, allowing for quick and seamless movement of goods. Their standard dimensions enable them to fit precisely onto pallet racks and into truck trailers, optimizing storage and transport processes. As a result, businesses can expedite their supply chain operations, reducing lead times and operational costs.

Reduced Environmental Impact

Sustainability is a growing concern in the logistics industry, with many companies seeking ways to minimize their environmental footprint. Single-Faced Grid Nine Feet Plastic Trays offer a sustainable alternative to traditional wooden pallets. They are not only reusable but also recyclable. This promotes a greener supply chain by reducing the need for constant disposal and replacement of pallets. Additionally, plastic trays are lightweight, which can translate to fuel savings and reduced greenhouse gas emissions during transportation.

Product Protection

Ensuring the safety and integrity of products during transportation and storage is a paramount concern in logistics. The grid pattern on the Single-Faced Grid Nine Feet Plastic Tray plays a significant role in this aspect. It prevents goods from slipping or sliding during transit, reducing the risk of damage. Moreover, plastic trays do not splinter or break as wooden pallets often do, further safeguarding products from harm. This results in fewer product losses, reducing costs and ensuring customer satisfaction.

Customization and Compatibility

One of the advantages of using plastic trays is their customization options. These trays can be designed to meet specific requirements, such as load capacity, dimensions, and material type. This customization allows businesses to optimize their supply chain operations according to their unique needs. Additionally, the compatibility of Single-Faced Grid Nine Feet Plastic Trays with various handling equipment, including forklifts and pallet jacks, makes them a versatile choice for a wide range of industries and applications.

Challenges and Considerations

While Single-Faced Grid Nine Feet Plastic Trays offer numerous advantages, there are challenges and considerations to be aware of. These include initial costs, recycling infrastructure, and potential issues with load capacity when compared to wooden pallets. Additionally, businesses must ensure that the trays are used and managed in an environmentally responsible manner to fully realize their sustainability potential.

If you are interested in our products or have any questions, please consult us.

英语

英语

志光证书.jpg?imageView2/2/w/500/h/500/format/jp2/q/100)

志光证书-2.jpg?imageView2/2/w/500/h/500/format/jp2/q/100)

志光证书-3.jpg?imageView2/2/w/500/h/500/format/jp2/q/100)

志光证书-4.jpg?imageView2/2/w/500/h/500/format/jp2/q/100)