Based on the principle of "quality-oriented, customer-driven, honesty essential", as well as the business philosophy of "leading in science and technology, pioneering and innovative, win-win cooperation", we continuously strengthen the quality management of our products and constantly strive to improve the level of service for our clients.

Product

+86-0576-88030503

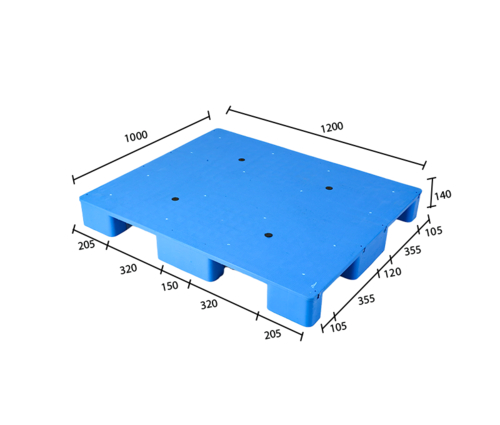

Flat/grid Big Nine Feet Manufacturer

-

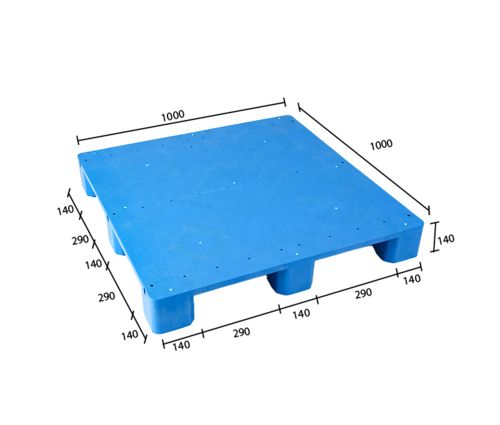

1010 Flat Big Nine Feet (3 Steel Can Be Added)

-

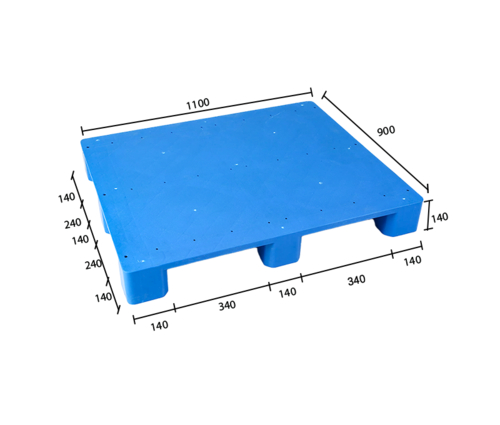

1109 Flat Big Nine Feet (3 Steel Can Be Added)

-

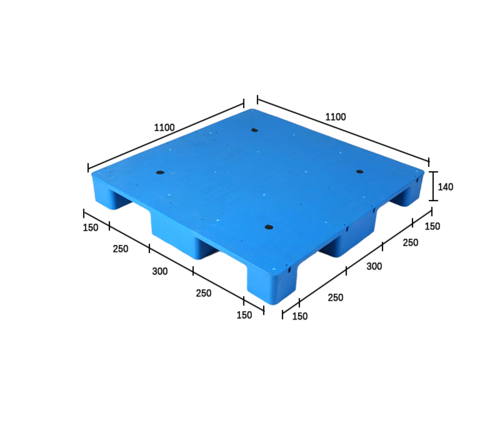

1111 Flat Big Nine Feet (4 Steel Can Be Added)

-

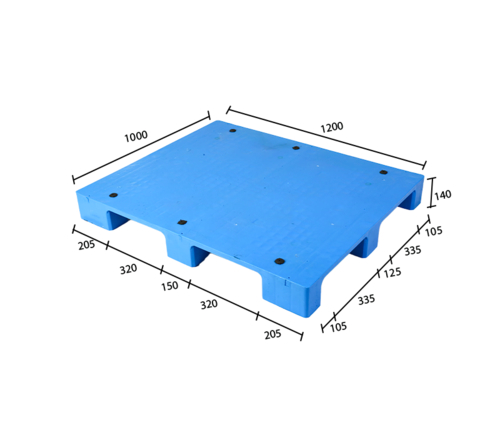

1210A Flat Big Nine Feet (3 Steel Can Be Added)

-

1210B Flat Big Nine Feet (4 Steel Can Be Added)

-

1212 Flat Big Nine Feet (4 Steel Can Be Added)

-

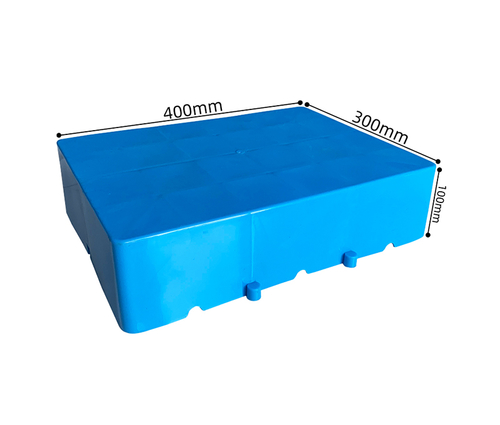

ZG-4030B Flat Box

-

ZG-4030B Four Feet Flat

-

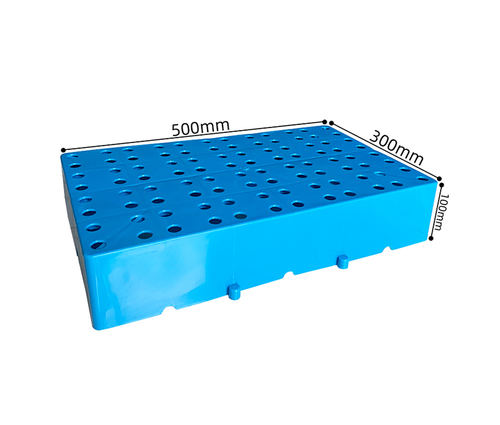

ZG-5030A Round Hole Box

-

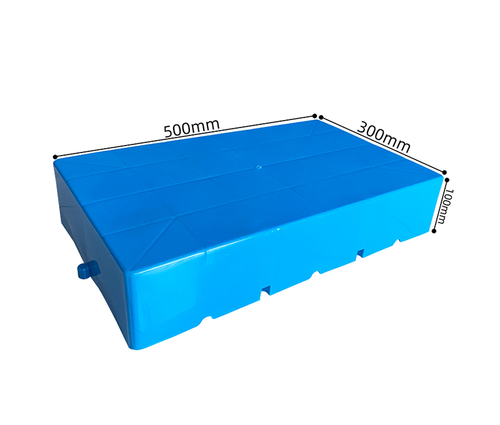

ZG-5030B Flat Box

-

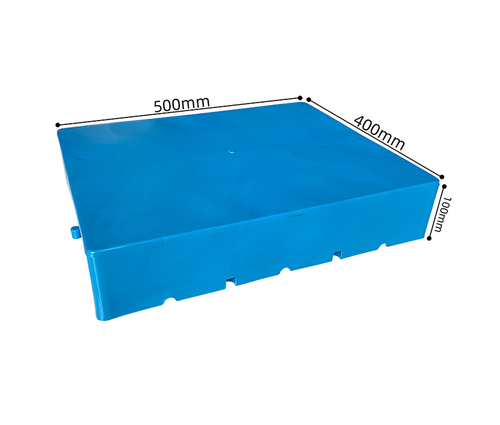

ZG-5040B Flat Box

-

ZG-5040B Four Feet Flat

Latest News

-

The role of the built-in steel pipe plastic tray

The main function of the built-in steel pipe in th...

-

Replacing wooden pallets with plastic pallets is the trend of the times

Plastic tray It is the most basic container unit i...

-

Plastic Storage Box Features

Actually, storage is not a huge deal. No matter ho...

-

Maximizing Playroom Space and Organization with a Toy Storage Rack

The Toy Storage Rack RevolutionToy storage racks h...

-

Maximizing Sustainability and Minimizing Waste: The Household Trash Can's Role in a Greener Future

The Evolution of the Household Trash CanThe househ...

-

Square Socks Underwear Storage Box: Organize Your Closet and Simplify Your Life

A cluttered and disorganized closet can be a sourc...

-

Organize Your Beauty Collection with the Three-Tier Drawer Makeup Box: A Comprehensive Guide

In the world of cosmetics and skincare, the allure...

-

The Environmental Impact of Dumping Boxes: A Closer Look at Waste Disposal Practices

Understanding Dumping Boxes:Dumping boxes, also kn...

-

Egg Storage Containers Box: Preserving Freshness and Enhancing Convenience

Eggs are a kitchen staple, versatile in countless ...

-

Cat Ear Desktop Storage Box: Feline Charm Meets Organizational Functionality

Organization meets aesthetics in a delightful fusi...

-

Three Classification Trash Cans: A Sustainable Solution for Waste Management

Waste management is an increasingly critical issue...

-

Organize with Elegance: The Oval Socks Underwear Storage Box

Efficient and aesthetically pleasing organization ...

How can the adoption of Flat/Grid Big Nine Feet Trays revolutionize the warehousing and e-commerce industries in the context of rapidly evolving consumer demands?

1. Space Optimization: Warehousing and e-commerce companies are continually seeking ways to optimize their storage space, given the increasing variety and volume of products they handle. Flat/Grid Big Nine Feet Trays, with their larger surface area and grid patterns, allow for efficient use of vertical space in storage facilities. This feature maximizes storage capacity while maintaining organization and accessibility.

2. Efficient Handling and Sorting: Quick and efficient handling of products is crucial for meeting consumer demands for faster order fulfillment. The larger footprint of these trays simplifies the sorting and organization of goods, streamlining the picking process. The grid pattern on the tray's surface adds stability, reducing the risk of products shifting during handling.

3. Durability for Heavy Loads: With the growing popularity of e-commerce, the need to handle heavier items, including electronics and appliances, has become more prevalent. Flat/Grid Big Nine Feet Trays are designed to withstand heavy loads, making them an ideal choice for warehousing companies that handle a diverse range of products. This durability ensures that trays can handle heavier items without compromising safety.

4. Customization for Varied Products: The e-commerce industry often deals with a vast range of product sizes and shapes. These trays can be customized to fit specific requirements, making them adaptable to the various products handled. The flexibility to customize the trays to the needs of different industries and businesses allows for a more streamlined and efficient process.

5. Sustainability and Reusability: Sustainability is an increasingly important aspect of warehousing and e-commerce operations. The plastic material used in Flat/Grid Big Nine Feet Trays is not only durable but also recyclable, making it an eco-friendly choice. Additionally, the trays' long lifespan and reusability reduce the need for frequent replacements, which can lead to cost savings and a lower environmental impact.

6. Safe and Streamlined Delivery: As consumers demand faster delivery, the efficiency of the last-mile delivery process becomes critical. The use of these trays helps in loading and organizing goods for delivery trucks, ensuring safe and streamlined transportation. Their durability minimizes the risk of damage during transit, improving the overall delivery experience.

the adoption of Flat/Grid Big Nine Feet Trays can bring about a revolution in the warehousing and e-commerce industries. These trays offer a solution to the growing challenges posed by the rapidly evolving consumer demands for efficiency, space optimization, and product diversity. By optimizing space, enhancing handling and sorting, accommodating heavy loads, and providing customization options, these trays can empower businesses to meet consumer expectations and streamline their operations.

their durability, recyclability, and potential cost savings make them an attractive choice for companies aiming to balance efficiency with sustainability. As the warehousing and e-commerce sectors continue to evolve, the integration of these trays may become a standard practice, ensuring the industry's readiness to meet the demands of consumers for faster, more diverse, and sustainable shopping experiences.

How can the adoption of Flat/Grid Big Nine Feet Trays transform the automotive manufacturing industry's logistics and supply chain operations?

The automotive manufacturing industry is known for its complex supply chain and logistics operations, where efficiency, precision, and safety are paramount. The adoption of Flat/Grid Big Nine Feet Trays offers significant potential to revolutionize these processes. These trays, known for their size, durability, and versatility, can address key challenges in the automotive industry and enhance various aspects of logistics and supply chain management.

1. Streamlined Component Handling: Automotive manufacturing involves numerous components of varying sizes and shapes. The use of Flat/Grid Big Nine Feet Trays provides a versatile solution for handling these components. The large size of these trays allows for the efficient organization and transportation of parts, reducing the need for frequent handling and minimizing the risk of damage.

2. Improved Assembly Line Efficiency: Efficient operations are crucial in automotive manufacturing. The grid pattern on these trays ensures that components remain stable during transportation within the assembly line, reducing the time and effort required for manual adjustments. This leads to improved efficiency, shorter production cycles, and cost savings.

3. Load Capacity for Heavy Parts: The automotive industry often deals with heavy components, such as engine parts, chassis, and transmissions. Flat/Grid Big Nine Feet Trays are designed to handle heavy loads, ensuring the safe transport of these critical parts. The durability of the trays also reduces the risk of damage during transit.

4. Customization for Different Models: Automotive manufacturers produce a range of vehicle models, each with its unique components. These trays can be customized to accommodate the specific requirements of different vehicle models. The ability to tailor the trays to the needs of various assembly lines can lead to improved organization and efficiency in production.

5. Environmental Responsibility: Sustainability is a growing concern in the automotive industry. The trays' material is not only durable but also recyclable, aligning with the industry's push for sustainable practices. Additionally, the reusability of these trays can lead to a reduction in waste and replacement costs.

6. Safety in Material Handling: Safety is a top priority in automotive manufacturing, where the handling of heavy and potentially hazardous materials is routine. The grid pattern on these trays adds stability, reducing the risk of accidents during transportation. This promotes a safer working environment for manufacturing personnel.

the adoption of Flat/Grid Big Nine Feet Trays has the potential to transform the logistics and supply chain operations in the automotive manufacturing industry. These trays address the unique challenges faced by the industry, such as the handling of diverse components, efficient assembly line operations, and the need for customization.

If you are interested in our products or have any questions, please consult us.

英语

英语

志光证书.jpg?imageView2/2/w/500/h/500/format/jp2/q/100)

志光证书-2.jpg?imageView2/2/w/500/h/500/format/jp2/q/100)

志光证书-3.jpg?imageView2/2/w/500/h/500/format/jp2/q/100)

志光证书-4.jpg?imageView2/2/w/500/h/500/format/jp2/q/100)