Based on the principle of "quality-oriented, customer-driven, honesty essential", as well as the business philosophy of "leading in science and technology, pioneering and innovative, win-win cooperation", we continuously strengthen the quality management of our products and constantly strive to improve the level of service for our clients.

Product

+86-0576-88030503

Double-faced Grid Manufacturer

-

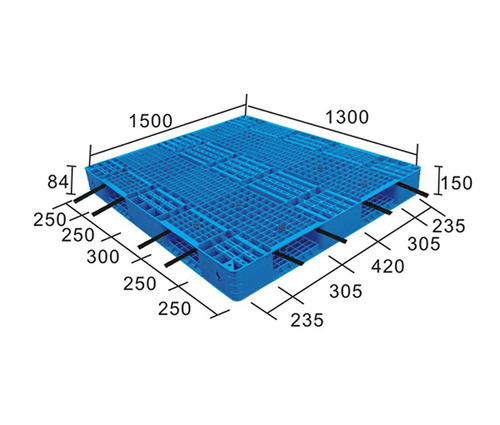

ZG-1513 Grid Double-faced

-

1111 Double-faced Grid

-

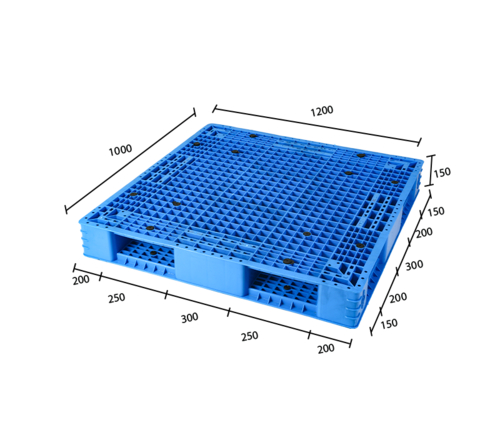

1210 Double-faced Grid

-

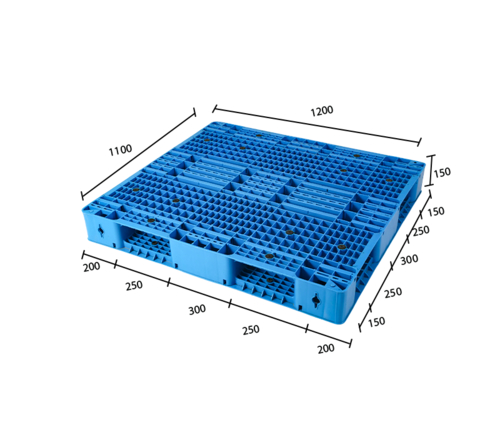

1211 Double-faced Grid (8 Steel Can Be Added)

-

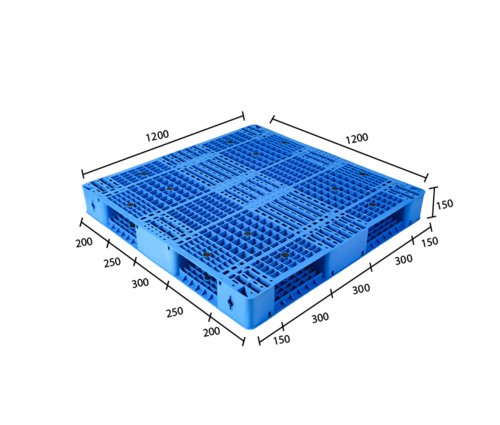

1212 Double-faced Grid (8 Steel Can Be Added)

-

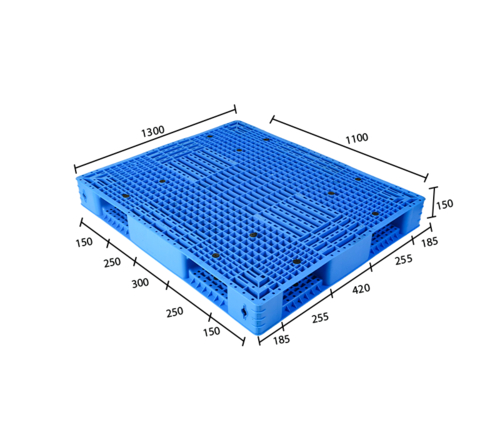

1311 Double-faced Grid

-

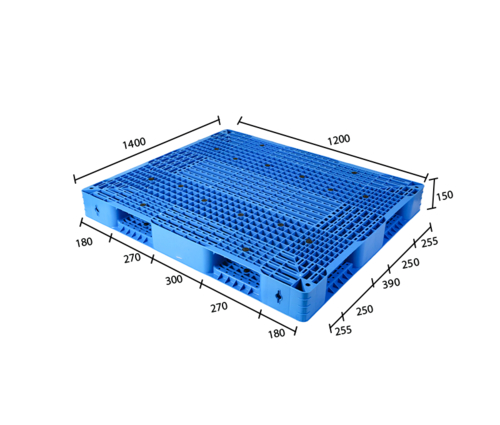

1412 Double-faced Grid

-

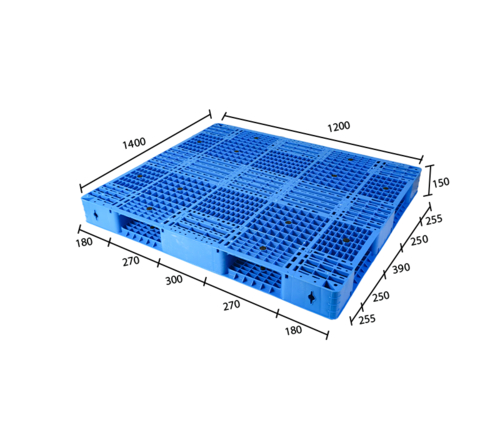

1512 Double-faced Grid (8 Steel Can Be Added)

-

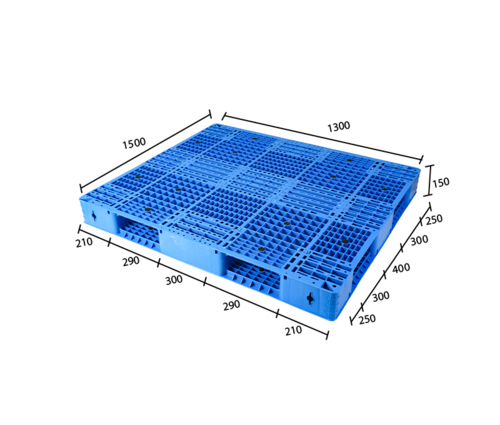

1513 Double-faced Grid (8 Steel Can Be Added)

Latest News

-

The role of the built-in steel pipe plastic tray

The main function of the built-in steel pipe in th...

-

Replacing wooden pallets with plastic pallets is the trend of the times

Plastic tray It is the most basic container unit i...

-

Plastic Storage Box Features

Actually, storage is not a huge deal. No matter ho...

-

Maximizing Playroom Space and Organization with a Toy Storage Rack

The Toy Storage Rack RevolutionToy storage racks h...

-

Maximizing Sustainability and Minimizing Waste: The Household Trash Can's Role in a Greener Future

The Evolution of the Household Trash CanThe househ...

-

Square Socks Underwear Storage Box: Organize Your Closet and Simplify Your Life

A cluttered and disorganized closet can be a sourc...

-

Organize Your Beauty Collection with the Three-Tier Drawer Makeup Box: A Comprehensive Guide

In the world of cosmetics and skincare, the allure...

-

The Environmental Impact of Dumping Boxes: A Closer Look at Waste Disposal Practices

Understanding Dumping Boxes:Dumping boxes, also kn...

-

Egg Storage Containers Box: Preserving Freshness and Enhancing Convenience

Eggs are a kitchen staple, versatile in countless ...

-

Cat Ear Desktop Storage Box: Feline Charm Meets Organizational Functionality

Organization meets aesthetics in a delightful fusi...

-

Three Classification Trash Cans: A Sustainable Solution for Waste Management

Waste management is an increasingly critical issue...

-

Organize with Elegance: The Oval Socks Underwear Storage Box

Efficient and aesthetically pleasing organization ...

How can the implementation of Double-faced Grid Plastic Trays revolutionize the food and beverage distribution industry and what benefits do they offer in a competitive market driven by efficiency and sustainability?

1. Enhanced Product Protection: In the food and beverage distribution sector, the safety and integrity of products are paramount. Double-faced Grid Plastic Trays offer superior product protection due to their grid pattern design, which prevents products from shifting or toppling during transit. This feature reduces the risk of damage, spillage, and spoilage, safeguarding the quality and safety of goods.

2. Increased Efficiency in Handling: Efficiency is a key factor in food and beverage distribution, where speed and accuracy are essential. These plastic trays are designed to facilitate quick and efficient loading and unloading. Their uniform dimensions and compatibility with various handling equipment, such as forklifts and conveyor systems, make them an ideal choice to expedite handling processes.

3. Customization for Diverse Products: The food and beverage industry encompasses a wide range of products, from delicate baked goods to heavy beverage containers. Double-faced Grid Plastic Trays can be customized to accommodate different product types, sizes, and weights. This versatility allows for efficient and organized handling of various goods, reducing the need for multiple types of containers.

4. Sustainability and Environmental Responsibility: Sustainability is a growing concern in the food and beverage industry. These plastic trays are environmentally friendly, made from recyclable materials, and can be reused numerous times. This aligns with the industry's increasing focus on reducing waste and carbon footprint while addressing consumer demands for sustainable practices.

5. Cost Savings: While plastic trays may have a higher initial cost compared to traditional options like wooden pallets, their durability and reusability lead to long-term cost savings. They require fewer replacements and repairs, and their protective design reduces the risk of product losses during distribution, resulting in cost reductions.

6. Hygiene and Sanitation: The food and beverage industry places a strong emphasis on hygiene and sanitation. Double-faced Grid Plastic Trays are easy to clean and disinfect, ensuring a sanitary transportation environment. Their non-porous surfaces do not harbor contaminants, making them a safer choice for distributing food products.

7. Reduction in Packaging Waste: The use of these trays can reduce the need for additional packaging materials, such as cardboard boxes and plastic wrap. This not only reduces waste but also simplifies the unpacking process for retailers and foodservice providers, saving time and resources.

the implementation of Double-faced Grid Plastic Trays has the potential to revolutionize the food and beverage distribution industry. Their benefits, including enhanced product protection, increased handling efficiency, customization options, sustainability, cost savings, hygiene, and waste reduction, align with the industry's evolving requirements for efficiency and sustainability.

As the industry continues to adapt to changing consumer preferences and regulatory requirements, the integration of these plastic trays may become a standard practice for food and beverage businesses aiming to enhance their distribution processes. Ultimately, Double-faced Grid Plastic Trays can help food and beverage companies meet the demands of a competitive market while reducing their environmental impact and improving the quality and safety of their products.

How does the use of double-faced grid plastic trays benefit the pharmaceutical packaging industry, and what are the key advantages and applications of this innovative packaging solution?

Advantages of Double-faced Grid Plastic Trays:

Enhanced Product Protection: Double-faced grid plastic trays provide an additional layer of protection for pharmaceutical products. The grid pattern offers stability and prevents items from shifting during transit, reducing the risk of damage. This is especially crucial for fragile or sensitive medications.

Excellent Visibility: The transparent nature of plastic trays allows for easy visibility of the products inside. This is essential for pharmaceutical packaging, where accurate inventory management and quality control are paramount.

Customizable Design: Manufacturers can easily customize double-faced grid plastic trays to suit the specific needs of pharmaceutical products. This includes designing compartments of varying sizes and shapes to accommodate different types of medications, ensuring a snug fit.

Reusability: Many double-faced grid plastic trays are designed for reuse, which not only reduces waste but also leads to cost savings over time. This is an eco-friendly approach that aligns with the pharmaceutical industry's growing emphasis on sustainability.

Easy to Clean: The non-porous nature of plastic trays makes them easy to clean and sanitize, a critical factor in pharmaceutical packaging to maintain the highest standards of hygiene.

Stackable and Nestable: These trays are often designed for efficient storage, both during transportation and in warehouses. They can be stacked and nested to optimize space, which is especially important when pharmaceutical companies are dealing with large volumes of products.

Applications of Double-faced Grid Plastic Trays in the Pharmaceutical Industry:

Medication Packaging: These trays are commonly used to package individual doses or vials of medications. The grid structure helps prevent breakage and ensures that each unit remains secure during distribution.

Medical Device Storage: Pharmaceutical companies often require the safe storage of medical devices and components. Plastic trays with compartments can keep these items organized and protected.

Laboratory Use: In research and development, where small quantities of samples and reagents are handled, plastic trays offer a convenient solution for organizing and transporting materials within the lab.

Cold Chain Management: For pharmaceuticals that require cold storage or transportation, double-faced grid plastic trays can be insulated or designed to fit cooling packs, ensuring the temperature-sensitive products remain within the required temperature range.

Clinical Trials: Pharmaceutical companies conducting clinical trials often need to distribute medications to different sites. Plastic trays can help ensure uniform and organized distribution, reducing the risk of errors.

Supply Chain Optimization: Using standardized, reusable plastic trays within the pharmaceutical supply chain can streamline logistics, improve inventory management, and minimize the risk of product damage during transit.

double-faced grid plastic trays have become an invaluable asset in the pharmaceutical packaging industry. Their versatile design, which prioritizes product protection, visibility, and customization, makes them an excellent choice for various applications within this highly regulated and sensitive sector. As pharmaceutical companies continue to focus on product safety, cost-efficiency, and environmental responsibility, the adoption of double-faced grid plastic trays is expected to remain on the rise, contributing to the overall success of the industry.

If you are interested in our products or have any questions, please consult us.

英语

英语

志光证书.jpg?imageView2/2/w/500/h/500/format/jp2/q/100)

志光证书-2.jpg?imageView2/2/w/500/h/500/format/jp2/q/100)

志光证书-3.jpg?imageView2/2/w/500/h/500/format/jp2/q/100)

志光证书-4.jpg?imageView2/2/w/500/h/500/format/jp2/q/100)