Based on the principle of "quality-oriented, customer-driven, honesty essential", as well as the business philosophy of "leading in science and technology, pioneering and innovative, win-win cooperation", we continuously strengthen the quality management of our products and constantly strive to improve the level of service for our clients.

Product

+86-0576-88030503

Blow Molding Tray Manufacturer

-

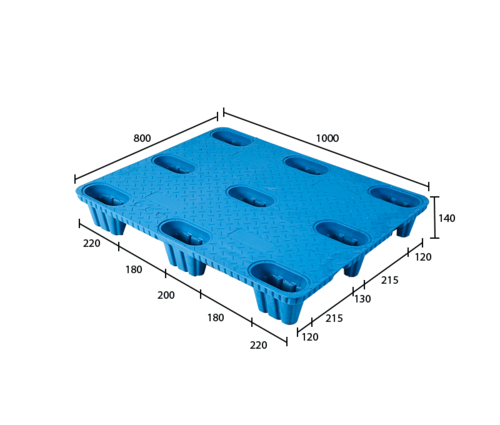

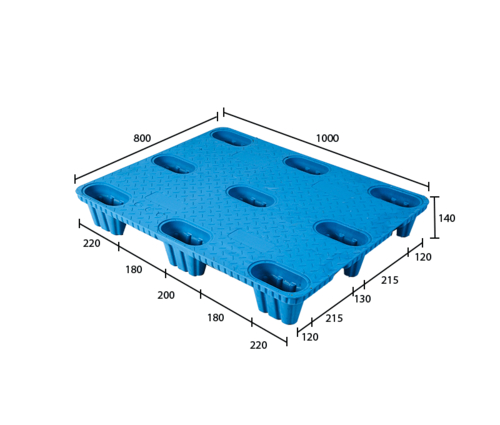

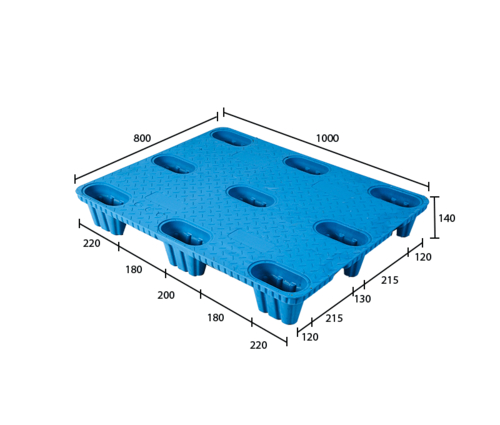

1008A Nine Feet Blow Molding

-

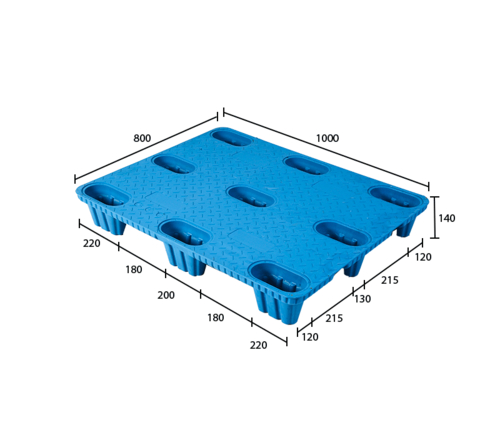

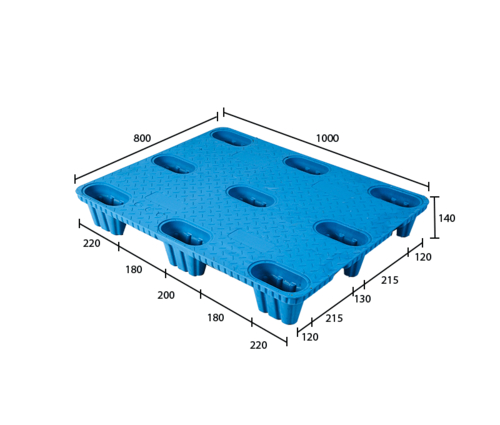

1008B Nine Feet Blow Molding

-

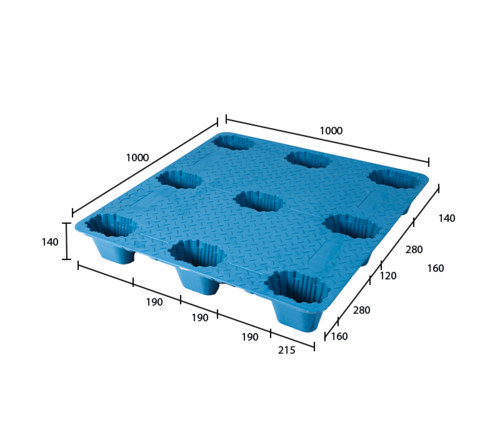

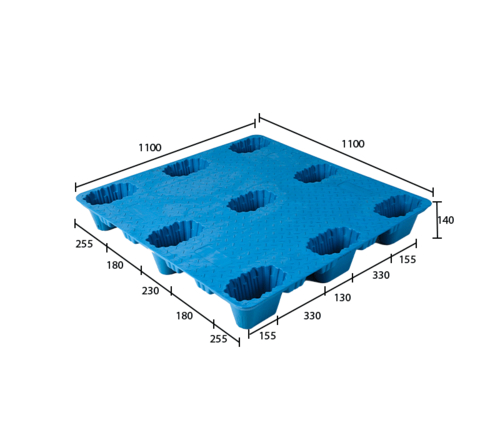

1010A Nine Feet Blow Molding

-

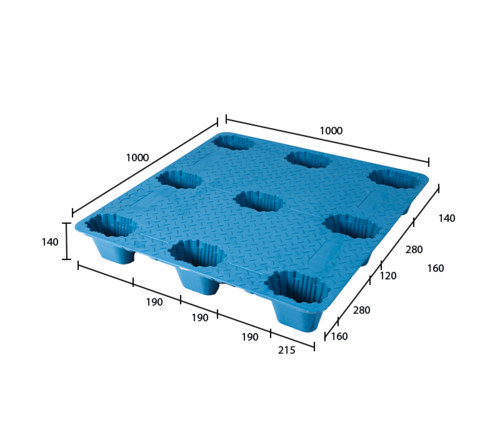

1010B Nine Feet Blow Molding

-

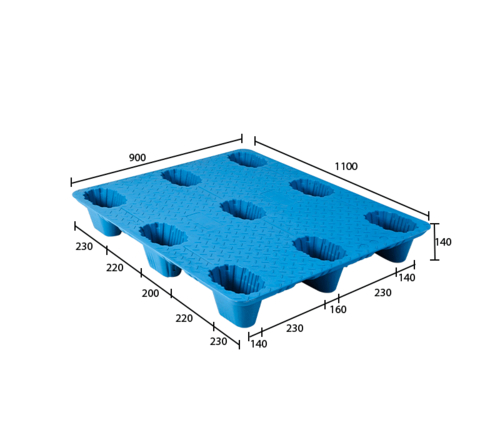

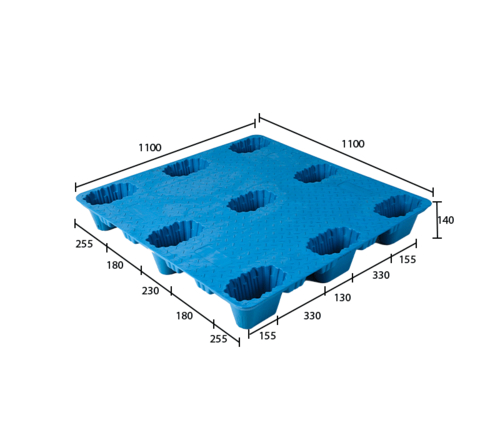

1109A Nine Feet Blow Molding

-

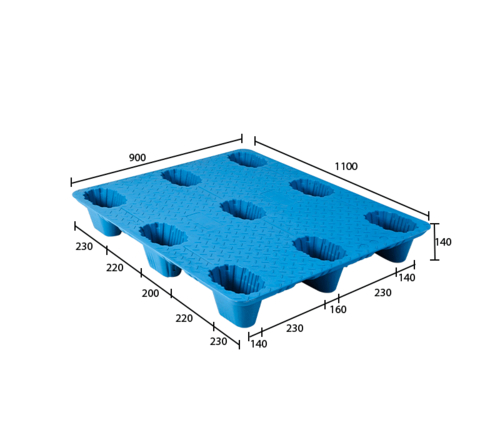

1109B Nine Feet Blow Molding

-

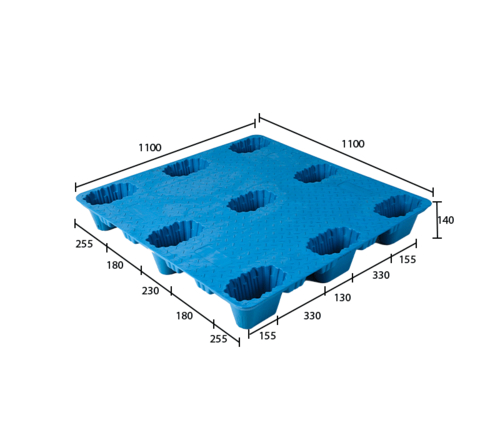

1111A Nine Feet Blow Molding

-

1111B Nine Feet Blow Molding

-

1111C Nine Feet Blow Molding

-

1111D Nine Feet Blow Molding

-

1111E Nine Feet Blow Molding

-

1111F Nine Feet Blow Molding

Latest News

-

The role of the built-in steel pipe plastic tray

The main function of the built-in steel pipe in th...

-

Replacing wooden pallets with plastic pallets is the trend of the times

Plastic tray It is the most basic container unit i...

-

Plastic Storage Box Features

Actually, storage is not a huge deal. No matter ho...

-

Maximizing Playroom Space and Organization with a Toy Storage Rack

The Toy Storage Rack RevolutionToy storage racks h...

-

Maximizing Sustainability and Minimizing Waste: The Household Trash Can's Role in a Greener Future

The Evolution of the Household Trash CanThe househ...

-

Square Socks Underwear Storage Box: Organize Your Closet and Simplify Your Life

A cluttered and disorganized closet can be a sourc...

-

Organize Your Beauty Collection with the Three-Tier Drawer Makeup Box: A Comprehensive Guide

In the world of cosmetics and skincare, the allure...

-

The Environmental Impact of Dumping Boxes: A Closer Look at Waste Disposal Practices

Understanding Dumping Boxes:Dumping boxes, also kn...

-

Egg Storage Containers Box: Preserving Freshness and Enhancing Convenience

Eggs are a kitchen staple, versatile in countless ...

-

Cat Ear Desktop Storage Box: Feline Charm Meets Organizational Functionality

Organization meets aesthetics in a delightful fusi...

-

Three Classification Trash Cans: A Sustainable Solution for Waste Management

Waste management is an increasingly critical issue...

-

Organize with Elegance: The Oval Socks Underwear Storage Box

Efficient and aesthetically pleasing organization ...

What are the main advantages and applications of this innovative technology, blow molded pallets?

Advantages of Blow Molding Trays:

Versatility: Blow molding trays are highly versatile and can be employed to produce a variety of container shapes and sizes, from small bottles to large industrial containers. This adaptability makes them suitable for a broad range of packaging needs.

Cost-Effective Production: The blow molding process is efficient and requires fewer raw materials compared to other manufacturing methods, leading to cost savings. This cost-effectiveness is particularly crucial for industries with high-volume production requirements.

Lightweight Containers: Blow molding results in lightweight yet sturdy containers, which are ideal for industries where minimizing packaging weight is essential, such as in the food and beverage industry for transportation and cost savings.

Customization: Manufacturers can easily customize the design, color, and labeling of blow-molded containers, allowing for brand differentiation and consumer appeal.

Sustainability: Blow molding trays are eco-friendly, as they are typically made from recyclable materials. This aligns with the growing emphasis on sustainability and environmentally responsible packaging solutions.

Speed of Production: Blow molding technology allows for high-speed production, enabling the rapid manufacturing of large quantities of containers to meet market demand.

Applications of Blow Molding Trays:

Beverage Industry: Blow molding trays are widely used in the production of beverage containers, such as water bottles, soft drink bottles, and juice containers. The lightweight nature of blow-molded containers reduces shipping costs and environmental impact.

Cosmetics and Personal Care: The cosmetics industry benefits from blow molding for creating containers for products like shampoo, lotion, and body wash. The ability to customize shapes and colors enhances brand recognition.

Food Packaging: Blow molding trays are essential for producing food packaging containers, including jars, tubs, and yogurt cups. The ability to create airtight and tamper-evident packaging is crucial for maintaining food quality and safety.

Chemical and Industrial Products: Industries requiring sturdy containers for chemicals, detergents, and industrial products often use blow molding technology. The lightweight yet robust nature of these containers is a significant advantage.

Pharmaceuticals: Blow molding trays play a role in the pharmaceutical sector for producing pill bottles, vials, and medical packaging. The ability to maintain product integrity and protect against contamination is vital in this industry.

Automotive and Lubricants: Containers for automotive fluids, such as motor oil and antifreeze, are often produced using blow molding technology. These containers need to be leak-proof and durable, making blow molding an ideal choice.

How has the adoption of blow molding trays transformed the packaging industry, and what are the key advantages and applications associated with this innovative technology?

1. Sustainability and Environment:

Blow molding trays have gained popularity due to their eco-friendly attributes. They are typically made from recyclable materials like HDPE (High-Density Polyethylene) and PET (Polyethylene Terephthalate). This reduces the environmental impact and aligns with the growing global concern for sustainability. The trays are also reusable, further minimizing waste.

2. Cost-Efficiency:

One of the key advantages of blow molding trays is their cost-effectiveness. The manufacturing process is highly efficient, with minimal material wastage. This leads to lower production costs, making it an attractive option for businesses aiming to reduce their packaging expenses.

3. Customization:

Blow molding trays can be tailored to fit specific product dimensions and shapes, making them ideal for a wide range of applications. They offer excellent product protection and can accommodate items with irregular forms, ensuring that products arrive at their destination in optimal condition.

4. Durability and Strength:

These trays are known for their durability and robustness. They provide excellent protection against shocks, vibrations, and external pressures during transportation. This attribute is crucial for industries such as electronics, pharmaceuticals, and food, where delicate or fragile items require safe and secure packaging.

5. Versatility:

Blow molding trays find applications in diverse industries, including agriculture, automotive, electronics, pharmaceuticals, and food. They are used for the packaging of fruits, vegetables, automotive components, medical devices, and more. Their versatility makes them a go-to choice for various sectors.

6. Hygiene and Safety:

In the food and pharmaceutical industries, hygiene and safety are paramount. Blow molding trays meet these requirements by being easy to clean, sterilize, and maintain. This makes them suitable for packaging food items, medicines, and medical instruments.

7. Reduction in Transport Costs:

The lightweight nature of blow molding trays reduces transport costs by minimizing fuel consumption and enabling more products to be transported in a single shipment. This helps in cutting down logistics expenses and reducing the carbon footprint.

8. Branding and Presentation:

Blow molding trays can be customized with branding and labeling, enhancing the visual appeal of products and promoting brand recognition. This is particularly important in industries where aesthetics play a crucial role in consumer choices.

9. Product Safety and Compliance:

For industries with stringent regulatory requirements, such as pharmaceuticals and medical devices, blow molding trays ensure product safety and compliance with industry standards and regulations. They are resistant to chemical reactions and contamination.

If you are interested in our products or have any questions, please consult us.

英语

英语

志光证书.jpg?imageView2/2/w/500/h/500/format/jp2/q/100)

志光证书-2.jpg?imageView2/2/w/500/h/500/format/jp2/q/100)

志光证书-3.jpg?imageView2/2/w/500/h/500/format/jp2/q/100)

志光证书-4.jpg?imageView2/2/w/500/h/500/format/jp2/q/100)